Ultrasound

Guide to Electrical Inspection with Ultrasound Technology

The Good, Better, and the Best approaches to lubricating bearings. Ultimately, are condition based approach using ultrasound to let the lubricator know when they have applied enough grease...

- Adrian Messer

- UE Systems

Setting Up a Lube Room

CBM CONNECT spoke with Clay to see what steps are involved in setting up a lube room in your facility...

- Clay Allen

- Mosaic

Ultrasound Provides Inspection Insight

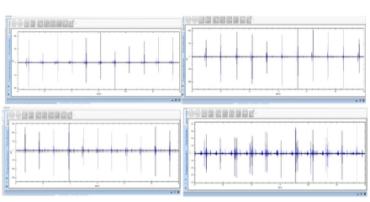

On a recent plant visit, solutions provider Bob Dunn with I&E Central, Inc. used the SDT 270 ultrasound instrument and a contact sensor to inspect and capture waveforms on a series of valves on an automated manufacturing machine...

- Bob Dunn

- I&E Central, Inc.

Test Your Ultrasound Knowledge!

Wondering how much you know about Ultrasound? Take the free quiz to find out...

- Martin Robinson

- IRISS Inc.

Introduction to IRISS Ultrasound EMSD’s

Learn how to use the Sonus XT with the IRISS VP12 US, VPDS and the S60 CAT Phone with the Sonus Vue APP...

- Drew Walts

- IRISS

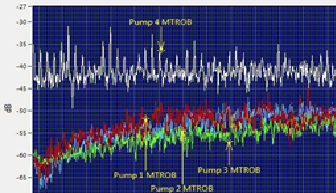

Slow Speed Bearing Monitoring & Other Condition Monitoring Applications

As maintenance and reliability professionals, we are tasked with the responsibility of ensuring that the assets that we are responsible for are operating the way that they were designed and installed for...

- Adrian Messer

- UE Systems

Sonus XT-Pocket Ultrasonic Testing Device

Six independent methods of rotor evaluation can be used from the MCEMAX technology to analyze the condition of a squirrel cage AC induction motor...

- Drew Walts

- IRISS

Lubrication Process Transformation

The Mosaic Company is a leader in crop nutrition and aims to help the world grow the food it needs. Reliability is essential to the company’s mission, and lubrication is a crucial part of its condition monitoring program...

Optimizing Your Lubrication Program With Ultrasound

Why is Ultrasound so easy to use to assist with your lubrication program. We can use ultrasound to optimize your preventative schedule, but also to completely use ultrasound to determine when and how much you need to grease...

- Peter Boon

- UE Systems Inc.

- 1

- …

- 5

- 6

- 7

- 8

- 9