Five Minute Facts

Sensor Reliability Impact on Predictive Maintenance Program Costs

Accelerometers with lower mean time between failures (MTBF) values result in higher costs for permanently installed vibration sensor applications - as much as $60 per vibration sensor. By taking the MTBF and manufacturing quality into account when making an accelerometer purchase, you can achieve lower overall program costs.

- Peter Eitnier

- Wilcoxon Sensing Technologies

Shaft Alignment 101: Offset & Angularity

Shaft alignment is a critical aspect of machinery maintenance, with the stationary shaft and movable shaft needing to be precisely aligned to avoid potential failures. In a typical setup, the movable shaft is adjusted relative to the stationary shaft to ensure alignment within machinery tolerances.

- ACOEM USA

- Acoem USA

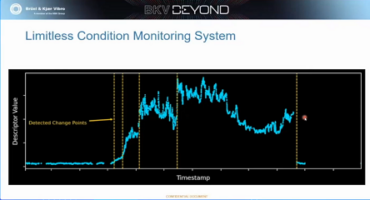

Working With a Limited Condition Monitoring System

What is the main purpose of the alarm threshold? It’s just to let us know that something has changed on this descriptor. This doesn’t mean a change in the data itself, but a change in the data distribution…

- Christian Benk

- Bruel&Kjaer Vibro

Motion Amplification in Oil and Gas Pumps

Motion amplification is an extremely versatile technology in the oil and gas industry. Paul Barna of RDI Technology presents examples of how it can be used on pumps and pipes…

- Paul Barna

- RDI Technologies

How Lubrication Reduces Energy Consumption

Machines use a lot of energy overcoming friction. John Sander discusses different types of lubricants and explains how they help your machines…

- John Sander

- Lubrication Engineers

The P-F Curve We Were Taught Kills Productivity and OEE

Roy Giorgio demonstrates why the older model of the P-F Curve can be misleading, using an example of a conveyor gearbox in which problematic data was disregarded…

- Roy Giorgio

- AssetWatch

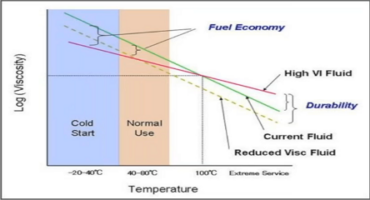

The Significance of Lubricant Viscosity

There have been significant changes in the lubrication industry recently, in which we have seen improvements in performance due to lower viscosity, resulting in decreased fluid friction…

- John Sander

- Lubrication Engineers

Industry’s Role in the Global Energy Outlook

One big reason we perform monitoring and maintenance is to reduce the amount of energy consumed by a machine, and by the plant as a whole. John Sander of Lubrication Engineers gives an overview of the global energy outlook…

- John Sander

- Lubrication Engineers

Motion Amplification 101: Camera Settings

Paul Barna of RDI Technologies demonstrates the features of the camera and software used in motion amplification, and the data we need to enter before taking a measurement in the field…

- Paul Barna

- RDI Technologies

- 1

- 2

- 3

- …

- 27