Ultrasound

When to go Wireless, and When Not

When it comes to condition monitoring, wireless technology is becoming ubiquitous for sensing applications. But many analysts still have a tried and tested portable monitor in their arsenal, so this begs the question, why should wireless sensors be used, and is there still a place for the more traditional route-based option?

- David Procter

- Sensoteq

Sensor Fusion: The Path to Proactive Plant Maintenance and Operational Excellence

A powerful approach for improving plant maintenance programs is the integration of multiple sensing technologies to improve coverage of machines and different failure modes. This can be further complemented by effective analysis of the data from all the different sources. When using multiple sensors like this, it is called Sensor Fusion...

- Alan McCall

- Sensoteq

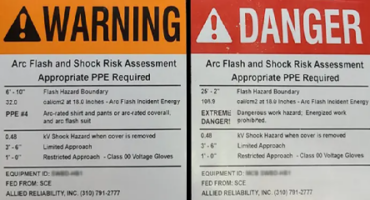

Arc Flash Studies: Why and When Are They Required?

For employees to work on exposed live (energized) circuits, an arc flash hazard assessment is needed to determine the incident energy available at the equipment and what personal protective equipment (PPE) is needed to work safely...

- Michael Levitt

- Allied Reliability

Detection of Gearbox Damage During Operation

Institute for Machine Elements at the University of Stuttgart detects smallest fraction on gear flank surface with the help of a SONOTEC ultrasound sensor.

- Christian Probst

- SONOTEC GmbH

Commercial and Industrial Power System Losses and Mitigation through Neutral and Ground

Even in discussions related to power harmonics most engineers, let alone reliability and energy professionals, understand the potential losses through the system. When it comes to harmonic content in neutral and ground in single and three phase systems, and the related losses, there has been limited attention...

- Howard Penrose

- MotorDoc LLC

Success Story: SONOTEC X PD Energy GmbH

Ultrasound is the technology for the first step in damage detection and has the advantage over other methods in that it can be used at all bearing speeds. Even with extremely low-speed bearings, damage can be detected at the earliest possible stage.

- Christian Probst

- SONOTEC GmbH

Avoiding Unplanned Downtime: Online Monitor of Critical Bearings

Keeping a close eye on the condition of critical equipment is fundamental in any industrial facility. When critical bearings fail, it almost always leads to unplanned downtime and interrupted production process, costing companies thousands in production loses. In this case study we will look at how an online monitoring solution using ultrasonic sensors was able to detect an issue on a critical bearing before it turned into a big problem.

- Peter Boon

- UE Systems Inc.

What’s New in Ultrasound Inspection?

Tom Murphy presents updates on acoustic cameras, continuous monitoring systems, on-condition lubrication, and process monitoring sensors (he warns that just because a sensor measures above 20 kHz, it doesn’t make it Ultrasound)…

- Tom Murphy

- SDT

Failure Detection using Ultrasound–Case Study: Slow-Speed Bearing on Oven Motor

Vibration analysis has long been the instrument of choice to use for bearings and other rotating equipment. More commonly, ultrasound is being used in conjunction with vibration analysis to help technicians confirm the condition of mechanical assets.

- Peter Boon

- UE Systems Inc.

- 1

- 2

- 3

- …

- 9