Webinars

How Generative AI is Transforming Predictive Maintenance

Discover how Artesis leverages ESA, machine learning, digital twins, and Generative AI to deliver expert-level diagnostics instantly, no specialist required. In this webinar, you’ll learn how these technologies work together to automate fault detection, improve reliability, and transform maintenance efficiency through real case examples and a live demo.

- Tumay Karaver

- Artesis Technology Systems

Exploring Solutions for Hydrogen Gassing in Wind & Solar Inverter Transformers

Hydrogen generation within inverter transformers has become a growing concern across renewable energy assets. Left unaddressed, it can signal insulation stress, early-stage faults, and long-term reliability risks. This webinar will address the issue of hydrogen gassing and degassing.

- Bob Rasor

- SDMyers

Motor Efficiency…It’s Not Enough!

While most industrial manufacturers now recognize the importance of motor efficiency, many still do not understand the technology’s significance or that resource efficiency is an additional key to maximizing productivity and profitability. It is imperative for officials to realize that motor efficiency without reduced power consumption is wasteful, motor efficiency without motor reliability is expensive, and motor efficiency and reliability without personnel safety is unnecessary.

- Noah Bethel

- PdMA Corporation

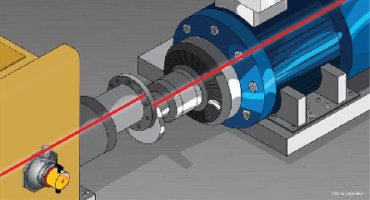

Data Repeatability in Shaft Alignment: Key to Accurate and Reliable Results

In precision shaft alignment, repeatability is the cornerstone of both confidence and credibility. Without consistent, repeatable data, even the most advanced alignment tools can produce misleading results, leading to improper corrections, increased vibration, premature wear, and costly downtime. This webinar will explore the critical role of data repeatability in shaft alignment and how it directly impacts maintenance efficiency, equipment reliability, and overall operational performance.

- Terry Southall

- Hamar Laser Instruments, Inc.

Bridging the Gap with Digital Vibration Monitoring 2.0

Industry 4.0 delivers new ways of boosting safety and maintenance regimes, and the related industrial infrastructures make it easy to integrate vibration trending into process monitoring and factory automation. The challenge comes in simplifying analog vibration data for digital protocols without sacrificing full spectrum vibration data that is valuable for machinery fault analysis. How can we bridge the gap?

- Peter Eitnier

- Wilcoxon Sensing Technologies

Innovations in Shaft Alignment: An Overview of Laser-Based Systems

This webinar will take attendees through the progression of shaft alignment technologies, starting from string lines and straightedges, through dial indicators, to today’s advanced laser alignment systems. We’ll explore how each method works, the benefits and limitations, and why modern industries are increasingly turning to laser-based solutions for critical machinery alignment.

- Terry Southall

- Hamar Laser Instruments, Inc.

Diagnosing AC Induction Squirrel Cage Rotors

Troubleshooting electric motors can be a complex effort. Even worse with a squirrel cage rotor in the field because you are without the ability to send test signals onto the rotor. This webinar will unveil six different methods to make the complex squirrel cage rotor troubleshooting more manageable.

- Noah Bethel

- PdMA Corporation

Optimizing Oil & Gas Operations with Advanced Condition Monitoring

In this webinar, we'll dive into the SETPOINT® solution and its unique ability to seamlessly integrate vibration data directly into the AVEVA™ PI System™. Discover how this capability is being used to monitor a variety of machines, including 37 reciprocating compressors, across 42 compressor stations along the 3,900-mile Northwest natural gas pipeline in the U.S.

- Michael Hastings

- Brüel & Kjær Vibro (B&K Vibro)

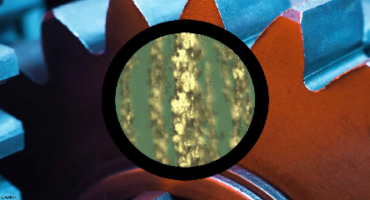

Benefit of Ferrography Analysis and Wear Debris Trending for Capital Asset

This webinar studies the health monitoring of a gear box by wear debris analysis.

- Premangshu Saha

- Tata BlueScope Steel

- 1

- 2

- 3

- …

- 40