Dennis Swanepoel

Company: WearCheck

Location: South Africa

Dennis started his career attaining my National Diploma(S4) in Mechanical Engineering and becoming a Performance and Testing Technician in the Power Generation Industry. He has been in the field of Condition Monitoring for the past 16 years. In his first years in condition monitoring he managed to be certified by Technical Associates as a trainer for their courses and started specializing in ODS and Modal Analysis. Dennis has worked in various industries and is qualified in Vibration, Thermography and Oil Analysis. Dennis also specializes in operational Deflection shape analysis. Currently, his main duties are shared between starting up new service contracts, Special Investigations, and Training (Mobius Training Partner).

Dennis has worked in industries that include: Power Generation, Coal Mining, Platinum/chrome refinery and mining, Waste Water Treatment, Food, Paper and Sugar Mills.

Ernesto Primera

Company: American Society of Mechanical Engineers

Location: North America/Latin America

Mechanical/Maintenance Engineer with 20 years of experience in Rotating Machinery, Condition Monitoring, Performance Analysis and Reliability Evaluations. Experience in the Oil and Gas Industry, Power Generation, Heavy Industry and OEMs. Proven experience working for ChevronTexaco, ConocoPhillips, Flowserve and SKF.

During the last years he has worked in the Rotating Machinery Reliability Department at the Pascagoula Refinery in Mississippi (CHEVRON) and Lake Charles Refinery in Louisiana (PHILLIPS-66). Global Instructor for the American Society of Mechanical Engineers (ASME), Industry Partner and Instructor for the Hydraulic Institute.

K.N.V “Subbu” Subrahmanyam

Company: Single Peak Lube Technologies

Location: India

Subbu is a Mechnical Engineer and certified CAT-III Lubrication Specialist, having 18 years of rich experience in lubricant monitoring and lubrication management with hands on experience of machinery lubrication related issues with various industrial segments like Cement, Steel, Petro-chemical, Power generation & Manufacturing etc. He is passionate to provide machinery lubrication trainings and conducted more than 150 trainings in India and overseas

He is a subject matter expert in Ferrography analysis, published and presented various technical papers nationally and Internationally on effective wear monitoring, Lubrication management and Lube oil analysis with Noria-Reliableplant, COMSOI,CMSI,TSI etc.Supports and works with non-profit organizations like Condition Monitoring Society of India, Tribology Society of India, etc and assists various national level educational institutes in the application studies of bio lubes and Wear monitoring.

Nolan Williamson

Company: Novelis

Location: North America

Nolan Williamson is a Reliability Engineer at Novelis aluminum, managing plant maintenance and reliability for a recycle and casting center in Atlanta, Georgia. Nolan has a university research background in mechanical vibrations.

Nolan is relatively new to the world of reliability and condition monitoring, but is excited to implement innovative reliability solutions to improve plant performance. He has a Bachelor’s of Science in Mechanical Engineering from the University of Georgia.

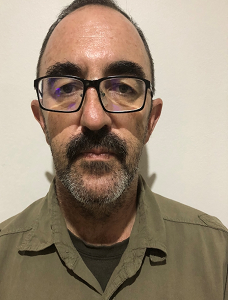

Paul Dufresne

Company: Reliability Playbook

Location: North America

Paul Dufresne has been president and CEO of Reliability Playbook since 2017, following 28 years of experience in maintenance and reliability roles in the U.S. Military and at Georgia Pacific, Trico Corporation and Koch Industries. As an enlisted soldier in the U.S. Army, Paul served six years of active duty and four years of National Guard duty. After completing his college education, Paul received his commission and served an additional four years of active duty as an officer in the Army’s Armor Branch.

He spent the next several years in the corporate world helping design and implement predictive maintenance programs and serving in a variety of roles in training, maintenance management and reliability leadership. In 2013, he received the Senior VP Award for Reliability from GP.

Pavel Yacobson

Company: International Paper

Location: Europe

Pavel Yakobson works for International Paper company as a Reliability Manager of EMEA [Europe, Middle East and Africa] region, being located in Gothenburg, Sweden. International Paper – the one of the world’s leading producers of fiber-based packaging, pulp and paper, operating more than 200 facilities with 52,000 employees in more than 24 countries.

Pavel’s 19-year career in Reliability has spanned from vibration technician to corporate SME [Subject Matter Expert], while developing and supporting a variety of Reliability programs. Most of this time was dedicated to Mechanical Precision and Predictive Maintenance services, consulting and training for the Power, Pulp & Paper and Steel industry, as well as Railway transport companies.

As a member of Russian National ISO TC 108/SC5 was involved to development and adaptation of ISO condition monitoring standards for the Russian speaking countries. Certified Mobius CAT III Instructor, Level 2 Infrared Thermography and Level I Ultrasound.

Rao Vamsidhar

Company: Visakhapatnam Steel Plant

Location: India

Rao Vamsidhar is a Maintenance Manager having a rich experience of 20 years in the rotating machinery field. He has begun his career as a Management Trainee in Power Engineering Maintenance department in Visakhapatnam Steel Plant, India in 1998 and successfully progressed and elevated to the position of Assistant General Manager in 2016. Throughout his career he is involved in the maintenance, condition monitoring and vibration analysis of high speed rotating machinery from turbines to balance of plant machinery.

He has been awarded Jawaharlal Nehru Award, highest recognition for best performance in Visakhapatnam Steel Plant in the year 2015. He is the 1st Indian to be certified as Cat IV vibration analyst from Mobius Institute in the year 2015.

Stefan Minnaar

Company: INPEX

Location: Australia

Stefan has been working in the condition monitoring field since 1994 and started his condition monitoring career in the power generation industry, he spent more than 13 years in coal- as well as 3 years in iron ore opencast mining in South Africa and Australia.

He had the responsibility of implementing condition monitoring programs (vibration-, lubrication-, performance monitoring- and NDT) on various sites across different industries. Stefan have been employed in the LNG industry since 2007 where he is responsible for the condition monitoring programs that covers a significant integrated online monitoring system on GE frame and aero-derivative turbines, various centrifugal- and axial compressors and cryogenic expanders and pumps and ancillary equipment.

Stefan specialises in vibration (turbo-machinery rotor-dynamic analysis via BN and B&K as well as balance of plant), thermographic analysis, motion amplification, airborne ultrasonic, rotating equipment inspection of turbo-machinery and lubrication analysis and has an in depth knowledge of API, ISO and relevant standards.

Tim De Block

Company: Fyraco Solutions

Location: Europe

Tim C. De Block is Managing director at the office of Fyraco Solutions. A company dedicated to predictive maintenance. Fyraco Solutions helps maintenance managers, by implementing predictive maintenance, to reduce maintenance costs. Tim has 20+ years’ experience in Vibration Analysis, and implementing Predictive Maintenance Programs. Tim also has 13 years’ experience as a level I Ultrasound and 8 years’ experience as a level 2 Thermography.

Matthew Moore

Company: Petrofac

Location: UK

Matthew Moore BSc (Hons) is the Global Subject Matter Expert in Condition Monitoring for Petrofac. He has over 25 years of experience in the field of vibration and condition monitoring and is a certified Mobius Institute ISO 18436-2 Category IV vibration analyst and training partner.

Matthew has extensive experience implementing vibration monitoring programmes and developing global guidance documents and condition monitoring strategies for the oil and gas industry. He is also the designer of CBMnet; Petrofac’s bespoke condition monitoring risk based reporting and information management system, which has been implemented on over 100 facilities in some of the remotest locations around the world.