Improper bearing lubrication is responsible for several issues, such as increased lubricant usage, increased bearing purchases (due to failures), increased equipment failures, increased operating temperatures, and motors that run inefficiently. Knowing this, we have to ask ourselves: Why do we not put more time, effort, and emphasis on our bearing re-lubrication procedures?

In fact, the majority of premature bearing failures are lubrication related and due to insufficient lubrication, over lubrication, using the wrong grease for that particular application, mixing incompatible greases together, or lubricant contamination.

Although Ultrasound has many uses and applications, one of the most important is assisted lubrication. Using ultrasound as a tool to assess lubrication levels allows us to know when we need to apply grease and when we have applied enough. It also tells us if there are other problems with the bearing. We can track and trend how much grease we are using on machines (a calibrated grease gun facilitates this) and optimize lubrication PMs (planned maintenance) for both time and frequency.

Traditional lubrication PMs are preventative procedures that are executed at time-based intervals with a specified amount of grease. However, there are a few issues with time-based re-lubrication: the bearing being lubricated may not need any more grease, the specified amount of grease may be too much or too little, and the lubrication frequency may be too high or too low. Typically, the tendency is to over lubricate, and ultrasound usually reveals that people have been applying too much grease.

Our goal, of course, when installing equipment is to extend the time between installation and the beginning of failure. When you install equipment, such as a motor and a pump, you probably do some precision alignment to make sure it is properly aligned. If it is out of alignment, that time window is shortened and the machine fails more quickly.

Proper lubrication extends bearing life, so it is important to make sure you are applying the appropriate amount. Ultrasound can help you do this, and it is also very good for finding early-stage premature bearing failures. There is significant overlap between ultrasound and vibration analysis. Vibration is better at detecting misalignment and unbalance. To know which technology to apply, you must understand how your assets can fail, and you must know which technology can find which types of failure.

Adding ultrasound monitoring to a plant’s current lubrication practices can help prevent failures due to over lubrication and under lubrication. This leads to extended bearing and equipment life, a decrease in the amount of lubricant used, more time for productive PMs, extended MTBF, and increased asset availability.

How Does Ultrasound Work?

Ultrasound instruments sense friction, the source of the high-frequency sound we are interested in. It is measured in decibels (dB). By nature, high-frequency sound is low energy, so measure at a point close to the bearing of interest. You can use a remote-access sensor if you cannot reach that area.

Friction is the main source of ultrasound when it comes to bearings. Another source of ultrasound is turbulence, often from compressed air and gas leaks. This includes internal turbulence across a valve or a steam trap. Ultrasound catches ionization from electrical faults, such as corona, tracking, and arcing. Ultrasound detects impacting, which mainly occurs with slow-speed bearings, as low as 1 rpm. A good 1 rpm bearing will be totally silent and will not register a decibel level. But if there is a fault, it can be heard on each rotation via ultrasound and will show up on a time waveform.

Ultrasound catches high-frequency sounds that are above what humans can hear. The upper-level threshold of normal human hearing, on average, is around 16 kHz–17 kHz. The ultrasonic range begins at 20 kHz. Ultrasound instruments can be fixed frequency (usually 38 kHz) or frequency tunable, or adjustable (usually 20 kHz–100 kHz).

A digital instrument, especially one that has frequency tuning, is recommended for better results and more repeatable data. For bearings and mechanical inspection, the frequency setting we recommend is 30 kHz. This goes back to a study done by NASA in 1974 in which scientists found they got the best results around 30 kHz. This has been confirmed by recent studies and is the recommendation of the ISO standard.

For slower-speed applications, below 100 rpm, lower the frequency to 20 or 25 kHz. Sound travels better via a solid, especially at lower frequencies. So when we make direct contact with a piece of equipment, we adjust that frequency lower.

Advantages of Ultrasound:

- It provides an early warning of failure.

- Ultrasound isolates the signal. High-frequency sound is low energy and will not travel far from the source. Ultrasound will pinpoint exactly where it is coming from.

- The quality of the bearing can be heard and visualized.

- Ultrasound easily detects bearings that are in need of lubrication.

- Ultrasound detects problems that cannot be found with traditional time-based lubrication routes.

- It is economical to implement. If a plant does not have a condition monitoring program, ultrasound is a good starting point.

- It can easily be used on slow-speed bearings.

- It complements other technologies such as vibration and infrared.

The technology you choose to implement depends on the failure modes of your most critical equipment and how early you want to detect failure mode. Companies have reported a tremendous return on investment from using ultrasound to monitor bearing lubrication. Because they were able to use lubrication effectively, their bearings lasted longer.

Key Points When Performing Ultrasound

Take great care to avoid introducing contaminants into the lubrication. To monitor how much grease you are using, calibrate your grease gun: there is a device that attaches to your grease gun and gives you an LED reading of how much grease you’re using, mass-wise.

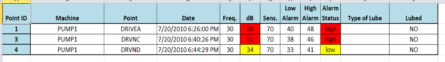

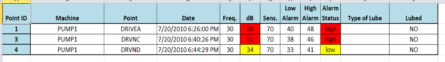

Consider using a remote-access sensor for bearings you cannot get close enough to. Listening to a bearing as you add grease is highly useful: One company found that the standard measure of 34 pumps of grease that they were using for a bearing was far from sufficient. In fact, the grease was probably not even reaching the bearing for some reason. The equipment actually needed 58 pumps.

To ensure repeatability when using ultrasound, make contact in the same location every time (you can use a mounting disk or paint to mark the spot), using the same frequency setting and the same contact method. The most sensitive piece of ultrasound equipment is the remote-access sensor. The second-most sensitive is the standard stethoscope-style contact probe, and the least sensitive is the magnet because the mass of the magnet attenuates the dB level slightly.

Use the same grease delivery method each time. Battery-operated grease guns are not necessary unless you need to pump the grease 12–15 feet. A simple, hand-pump grease gun is usually sufficient.

There are digital and analog ultrasound instruments. A digital instrument allows for trending, setting baselines and alarm levels, and tracking grease usage. Some instruments have onboard sound recording for FFT and TWF analysis. Analog instruments are good for operators and lubricators because they are easy to use and inexpensive.

What Can We Expect to Hear?

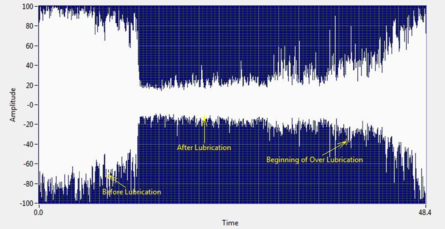

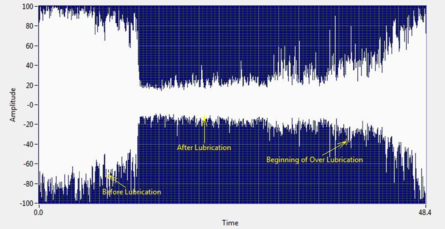

- If the bearing needs grease, the dB will decrease as lubricant is applied because there will be less friction.

- If the bearing is already sufficiently lubricated and does not need any grease, the dB will start to increase as lubricant is applied.

- If there was no change in dB while greasing, it’s usually due to one of the following issues: The bearing is in a failure mode that is beyond the help of lubrication. Or, if the bearing has previously been over lubricated, and the seal is compromised, all of the excess grease being applied is likely going into areas of the equipment where it should not be. Therefore, the dB will not change.

- If ultrasound routes for data collection are in place, a follow-up reading should be taken on the most critical assets to ensure that the dB did not return to the pre-lubrication level after lubrication. Complementary technology can be used for this, especially if a high alarm has been reached.

- Depending on the ultrasound data, lubrication PMs may need to be adjusted for the frequency of lubrication and the amount of lubricant applied. You can even fine-tune auto-lube systems through the use of ultrasound.

If you would like to implement ultrasound assisted lubrication in your plant, there are three ways to do it: a good way, a better way, and the best way.

Ultrasound Assisted Lubrication: Good Approach

- Lubricate the equipment according to the manufacturer’s recommendations

- Take it a step further and calculate the amount of grease to apply based on bearing size and dimensions

- Consult with your lubricant supplier to ensure that the correct lubricant is being used for the right application

- Determine lubrication frequency based on equipment runtime and operating conditions

Ultrasound Assisted Lubrication: Better Approach

- If time-based bearing lubrication PMs are in use, add an ultrasound instrument to the procedure of greasing bearings

- This will, at least, let the lubricator know when to stop applying grease

- Bearing failures that were previously unknown will be identified

- It is very typical to see a reduction of at least 30% in grease consumption

Ultrasound Assisted Lubrication: Best Approach (Condition Based)

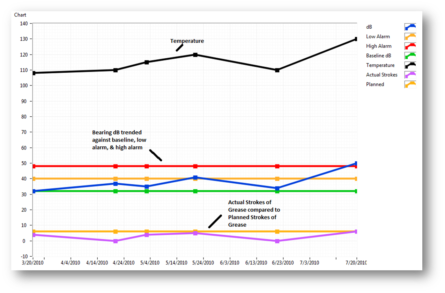

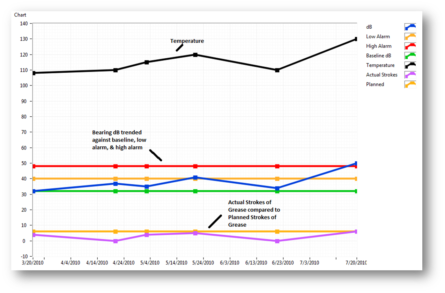

- Use an ultrasound instrument with data-collection capabilities to record both dB and sound files and trend the files over time

- Establish routes for data collection to set baselines and alarm levels

- Recommended alarm levels should be set:

- 8 dB above the baseline indicates a lack of lubrication

- 16 dB above the baseline indicates a more severe fault

- Instead of applying grease to all bearings, only the bearings that are in the low-alarm condition should be greased, until they reach the baseline dB

- Move toward condition-based lubrication rather than time-based lubrication

- For more critical assets or additional diagnostics, a new sound file can be recorded and compared to the baseline sound file recording

- More problems will be found using ultrasound

- You will also see better reporting and documentation

It assists with RCM and RCA events