Case Studies and Stories

How to Analyse a Bearing Condition

This case study is done in association with a global rail company where VibCloud is utilised for ongoing locomotive monitoring for many years now. Case study demonstrates how to analyse vibration in order to determine bearing condition.

- Petar Spaseski

- iTnnovate

Rotor Bar Fault Maintenance Issue: Vibration Sensor Alert

A 398 KW MV motor that runs a blower fan in a cement plant was showing strange behavior. The vibration equipment indicated vibration amplitudes that became chronic with the passage of time. The maintenance team, not knowing what the issue was, ran the motor until the bearings had to be replaced...

- Mark Koch

- ALL-TEST Pro, LLC

How We Diagnosed Our Cooling Water Pump Gearbox

This case study comes from a custom-made, four-story-high pump at Engro Fertilizers. In January 2014, we started noticing abnormal noise and vibration from the gearbox. But we couldn’t see anything apart from an increased gear mesh frequency…

- Haider Ali

- Engro Fertilizers

Vibration Analysis report of Broken/Cracked Rotor Bar

In March of 2016, the vibration for Turbo Blower 2 was normal, but the motor temperature had increased. Ten days later, however, it was running rough with periodic noise...

- Muhammad Trendo

- Indah Kiat Pulp & Paper Perawang

HD Technologies Case Study: Ball Mill Bearing Damage

This case study describes bearing damage detected through online measurements taken from a ball mill at the flotation plant of Asarel Medet AD in Bulgaria. At the beginning, the SPM HD trend had varying shock pulse levels...

- Dobromir Dobrev

- SPM Instrument Bulgaria EOOD

Hear Failure from Miles Away

Experienced maintenance professionals can understand if a machine is healthy or not by walking up to it and using their senses – hearing, touch, smell, and sight. But this skill doesn’t scale when there are more plants than experts. This case study – a TechINSIGHT – shows how IoT maintenance solutions are helping machine analysts be in multiple places at once...

- Brett Burger

- National Instruments

HD Technologies: Press Roll Bearing Damage Detection

At a Romanian paper mill called Vrancart S.A., the online system Intellinova Compact with HD condition monitoring technology is installed to monitor the press section of paper machine K25. This case study involves the detection of bearing damage on one of the press rolls, showing the development of the damage over a period of about six weeks…

- Dobromir Dobrev

- SPM Instrument Bulgaria EOOD

Detecting Vortex Rope in a Francis Turbine Operating at Partial Load

The dynamic behavior at part load has been a major problem for low head and medium head Francis turbines...

- Emre Orhon

- Pro-Plan Ltd. - Istanbul Turkey

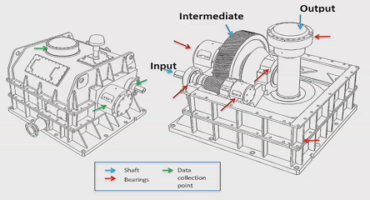

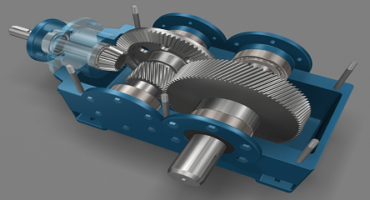

Best Practice in Gearbox Monitoring

Vibration monitoring on gearboxes is not obvious. Brand new gearboxes do have vibrations. Therefor putting alarm detection based on overall vibration levels often leads to false alarms or missed fault detection...

- Jos Sas

- Allied Reliability Group

- 1

- 2

- 3