Vibration Analysis

Operator-Driven Reliability: Empowering the Front Line for Better Asset Performance

In any industrial facility, operators are the first line of defense against equipment failure. They are closest to the machines, see them every day, and often notice the earliest signs of trouble. This is the foundation of Operator-Driven Reliability (ODR)—a proactive approach that empowers operators to take ownership of equipment health and contribute directly to reliability outcomes.

- Shaiful Hady Mohamad

- Handy Engineering

Tag It Right: Equipment Tagging Using ISO 14224 for Smarter Maintenance and Analysis

Effective asset management starts with clear identification—and that's where equipment tag numbering comes into play. In industrial settings, especially where reliability and maintenance data are critical, standardized equipment tagging isn’t just helpful—it’s essential.

- Shaiful Hady Mohamad

- Handy Engineering

Digital Accelerometers vs. Digital Adapters: Selecting the Right Sensor for Your Application

As industrial monitoring shifts toward digital data, engineers are evaluating how best to integrate vibration data into control and analysis systems. Two leading approaches—digital accelerometers and rugged industrial IEPE accelerometers paired with digital adapters—offer distinct trade-offs in performance, reliability, and environmental suitability. Understanding these differences ensures you select the most reliable and suitable solution for your application.

- Tom LaRocque

- Wilcoxon

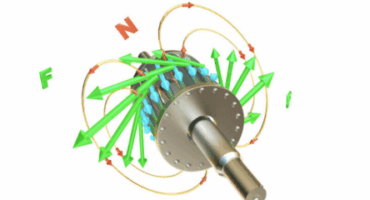

Optimizing Vibration Sensor Positioning: A Key Step Toward Reliable Condition Monitoring

In condition monitoring and predictive maintenance, vibration analysis is one of the most effective techniques for detecting early signs of mechanical failure in rotating machinery. However, the accuracy and value of vibration data heavily depend on one critical factor: correct sensor positioning.

- Shaiful Hady Mohamad

- Handy Engineering

Failure Mode and Effect Analysis (FMEA): A Proactive Tool for Managing Risk

In industrial and engineering environments, the ability to foresee and prevent failure is a key element of effective asset management. One of the most practical and widely adopted methodologies for this purpose is Failure Mode and Effect Analysis (FMEA).

- Shaiful Hady Mohamad

- Handy Engineering

Magnetostriction: The Reason for 100Hz or 120Hz Vibration in Electric Motors

Whenever a magnetic object or ferrous object is subjected to a magnetic field, it reacts to the forces. This phenomenon is called magnetostriction.

- Wael Salman

- Dietsmann France

Choosing the Right Maintenance Strategy

Maintenance is more than just fixing what’s broken—it's a strategic discipline that directly impacts uptime, cost efficiency, safety, and asset longevity. With increasing pressure on operational performance, selecting the right maintenance strategy for each asset is no longer optional—it’s essential.

- Shaiful Hady Mohamad

- Handy Engineering

From the Plant Floor to the Cloud: Digital Vibration Sensors and Adapters Explained

Discover the key differences between digital vibration sensors and digital adapters - two powerful technologies driving smarter, data-driven maintenance. Learn how each plays a role in capturing rich vibration data, optimizing performance from the plant floor to the cloud.

- Tom LaRocque

- Wilcoxon

Beyond the Quick Fix: Unlocking True Root Cause Analysis

Quick fixes may restore operations temporarily, but they rarely eliminate the real problem behind equipment failures. Root Cause Analysis (RCA) digs deeper to identify and correct the underlying issues, ensuring long-term reliability and preventing repeat breakdowns.

- Shaiful Hady Mohamad

- Handy Engineering

- 1

- 2

- 3

- …

- 30