Five Minute Facts

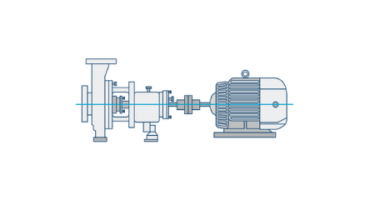

Detecting and Diagnosing Misalignment in a System

Next-generation sensors based on MEMS technology, combined with advanced algorithms for diagnostic and prognostic applications, expand opportunities to measure a variety of machines and improve the ability to effectively monitor equipment, improve uptime, enhance process quality, and increase throughput. This 5 minute fact reviews misalignments and their characteristics to provide insights into some of the key system requirements that must be considered when developing a condition-based monitoring solution.

- Pete Sopcik

- Analog Devices, Inc

How to Cut Your Time in Measuring For Misalignment Issues

PRUFTECHNIK sensALIGN technology upgrades ancient angularity and offset measurement practices..

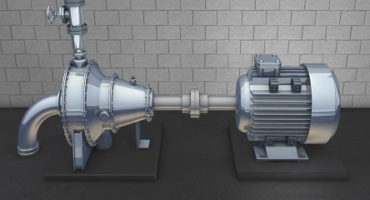

Verification & Validation

Three different rotor kits with particular balancing equipment will be considered here...

- Jose Mendez Adriani

- Central University of Venezuela

Representing Your Data

Before we can represent the data, we need to ensure that we capture appropriate data. The data that we need is amplitude at a particular frequency...

- Dennis Swanepoel

- WearCheck

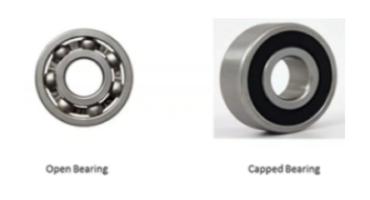

How to Choose A Capped Bearing

In this Five Minute Fact, we will discuss how a capped bearing differs from an open bearing. Capped bearings do not have a visible opening so why choose them?..

- Akhil jeet Rathore

- Indorama Petrochemicals & Fertilizers

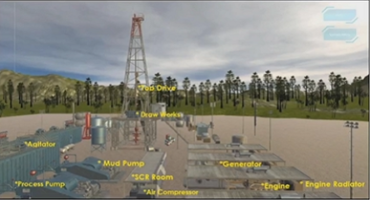

The Basics of Rigs: the Vital Role They Play in Exploration

Offshore, or marine, rigs are based on sea and onshore rigs are based on land. We select the type of rig based on the geological location and how deep we need to drill. The major concept of rigs is...

- Nishanthan Senkuttuvan

- Osborne Engineering Limited

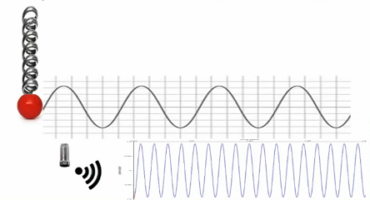

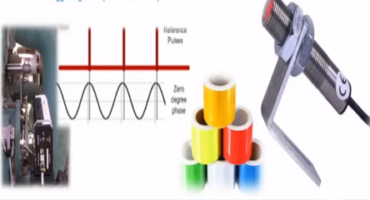

Poor Man’s ODS: Phase

In the second series of the Poor Man's ODS we will look into phase. All Fast Fourier Transforms, know as FFT contain three characteristics of Vibration. Learn the 2 accurate and practical phase techniques to measure phase....

- Dennis Swanepoel

- WearCheck

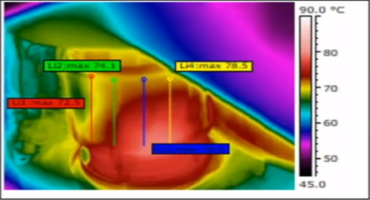

A Closer Look at Thrust Ball Bearing Damage

Thrust bearings are usually located on the non-drive end of the equipment. This is a small pump you'd expect to be driven by a motor. But the bearings of horizontal motors are not designed to...

- Ali Al-Shurafa

- Saudi Aramco

When Do You Need ODS?

The study of a machine's motion is called Operational Deflection Shape (ODS). This study should be done when the machine is in a steady-state or normal operation. Find out the different types and why you would use ODS...

- Dennis Swanepoel

- WearCheck

- 1

- 2

- 3