Verification & Validation

Three different rotor kits with particular balancing equipments will be considered.

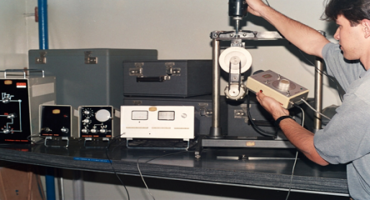

a. Balancing Equipment: model TM2, analyzer RS 3164, transducer PMG 48/S and stroboscope BG-No 707.00.020

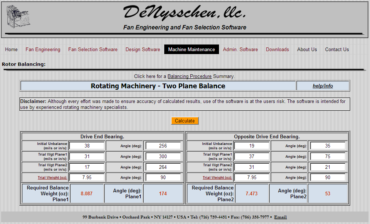

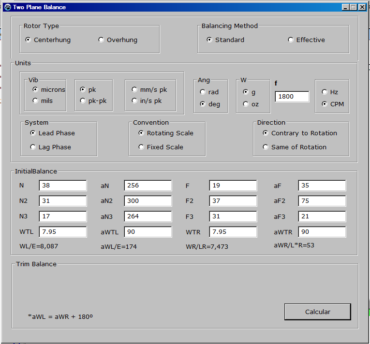

Rotor Type: Centerhung

Balancing Method: Standard

Units:Vib: microns pk, Ang: deg; W: g;f=1800CPM

Data: in p. 174 of Reference 15 of Reference 1

System-Convention-Direction:Lead Phase-Rotating Scale-Contrary to Rotation

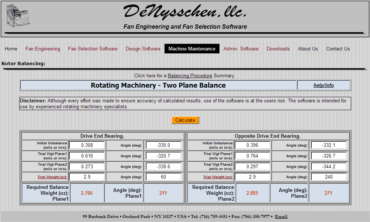

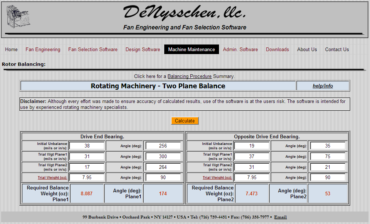

Used: on-line software in Reference 5

A>Data

N= 3.80000000000000E+001 d= 2.56000000000000E+002

F= 1.90000000000000E+001 e= 3.60000000000000E+001

Wtn= 7.95000000000000E+000 atn= 9.00000000000000E+001

N2= 3.10000000000000E+001 d2= 3.00000000000000E+002

F2= 3.70000000000000E+001 e2= 7.50000000000000E+001

Wtf= 7.95000000000000E+000 atf= 9.00000000000000E+001

N3= 1.70000000000000E+001 d3= 2.64000000000000E+002

F3= 3.10000000000000E+001 e3= 2.10000000000000E+001

Correction

Wn= 8.11252594400786E+000 an= 1.74367731945662E+002

Wf= 7.48493423362498E+000 af= 5.29374868807743E+001

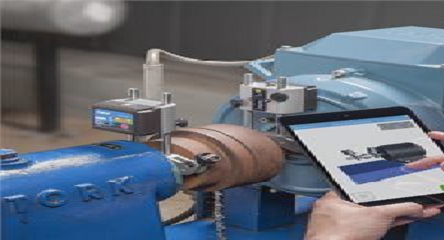

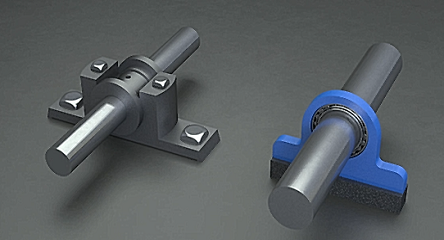

b. Balancing Equipment: rotor kit IRD Mechanalysis (model TM2 shown in the photograph), balancer Entek IRD 885, accelerometers IRD 970 and photocell Entek IRD 21000

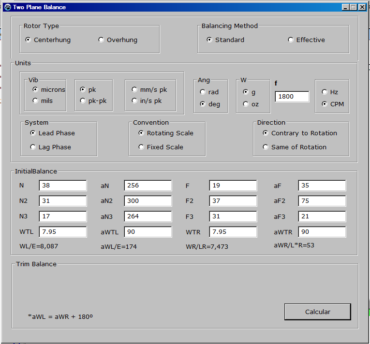

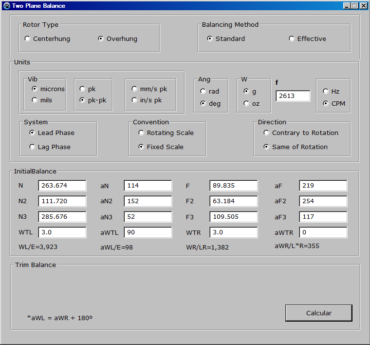

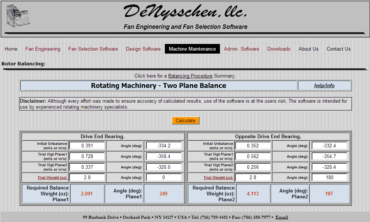

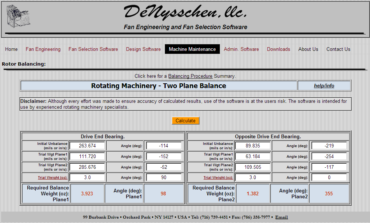

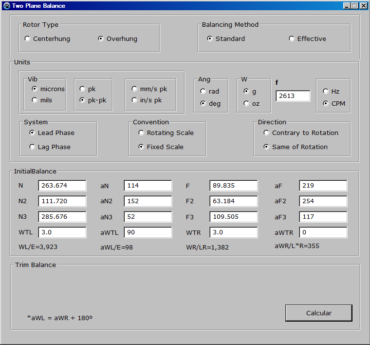

Rotor Type: Overhung

Balancing Method: Standard

Units: Vib:microns pk-pk, Ang: deg; W: g;f=2613CPM

Data: in Reference 1

System-Convention-Direction:Lead Phase-Fixed Scale-Same of Rotation

Used: on-line software in Reference 5

Table 1. Recorded data and corrections.

| Commonto all methods |

| N=263.674 mm |

d=114° |

F=89.835 mm |

e=219° |

| WTL=3.0 g |

aTL=90° |

|

|

| N2=111.720 mm |

d2=152° |

F2=63.184 mm |

e2=254° |

| Standard method |

| |

|

WTR=3.0 g |

aTR=0° |

| N3*=285.676mm |

d3*=52° |

F3*=109.505mm |

e3*=117° |

| WL*=3.942 g |

aL*=98° |

WR*=1.397 g |

aR*=355° |

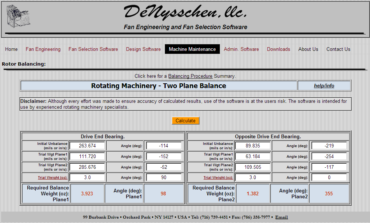

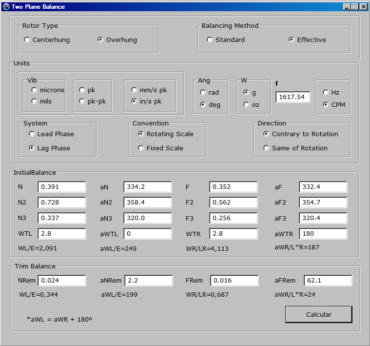

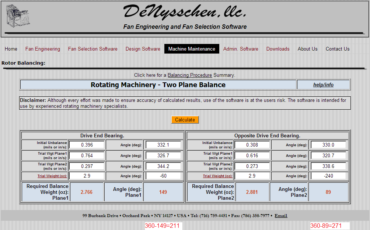

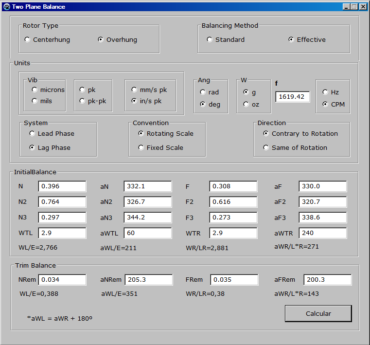

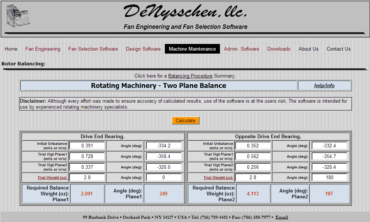

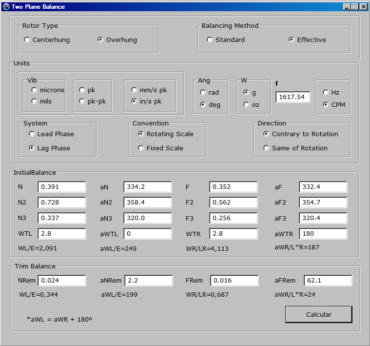

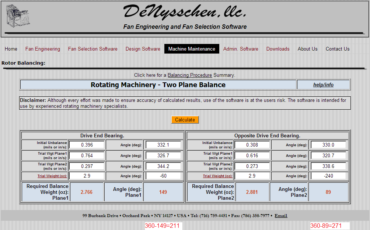

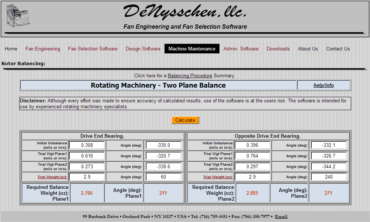

c. Balancing Equipment:prototype, analyzer MicroVib II DSS, accelerometers P/N 1880 and photo tachometer MINI-BEAM P/N 1015 BANNER

Rotor Type: Overhung

Balancing Method: Effective

Units: Vib: in/s pk, Ang: deg; W: g; f=1617.54CPM

Data: in Reference 4

System-Convention-Direction: Lag Phase-Rotating Scale-Contrary to Rotation

Used: on-line software in Reference 5

Used: balance program in Reference 6 (Lead Phase-Fixed Scale-Same of Rotation)

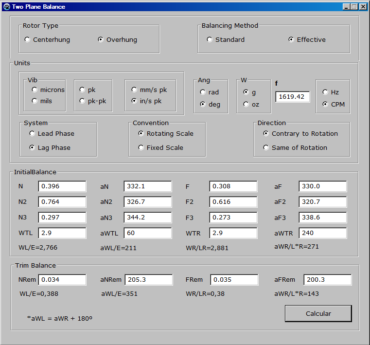

Units: Vib: in/s pk ,Ang: deg; W: g;f = 1619.42CPM

New Data:

System-Convention-Direction: Lag Phase-Rotating Scale-Contrary to Rotation

Used: invariance in Reference 3 and on-line software in Reference 5

Used: balance program in Reference 6 (Lead Phase-Fixed Scale-Same of Rotation)

Proof of item (c) to check the computer program

Conclusion: Comparable results were obtained for each case. Here, the verification of the computational solution is done by comparison with the standard solution. And, the validation of the computational model is done by comparison with the rotor kit.