While wear is considered the main cause of failure in machinery, and preventing it should be a main focus for maintenance teams, there are a few other conditions that need to be closely monitored. These include imbalance, misalignment and looseness. These conditions, if left uncorrected, manifest themselves in damaged components, as well as associated collateral damage.

So, what are imbalance, misalignment and looseness?

Imbalance

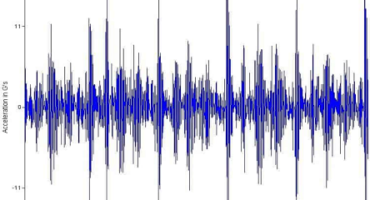

Imbalance occurs when the centre of mass differs from the centre of rotation. This creates a centrifugal force, leading to high vibration amplitudes at frequencies equal to 1xRPM (1x rotational speed) in spectral data, with a sinusoidal waveform in the time domain.

On rigidly mounted machines, amplitudes will typically be highest in the horizontal direction rather than the vertical direction, although raised amplitudes can also exist axially on overhung rotors. The imbalance amplitude will increase by the square of speed (when the running speed is below the 1st rotor critical frequency). Typically, a 90-degree phase difference will exist between horizontal and vertical readings at each bearing with a pure imbalance problem.

Misalignment

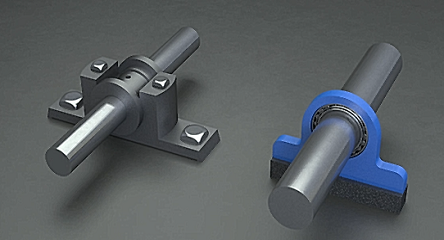

Misalignment occurs when the shaft centrelines of two directly mating components meet at angles and/or are offset from one another. Misalignment of couplings and bearings typically results in high radial and/or axial vibration.

Angular misalignment typically produces higher axial amplitudes with a phase difference of 180-degree axially across the couplings. Offset misalignment generally produces high radial amplitudes with a phase difference of 180-degree radially across the couplings. A misalignment problem will typically produce dominant frequencies at 1xRPM and/or 2xRPM, depending upon the degree of angular misalignment against the offset misalignment, as well as the type and design of the couplings.

In situations where 1xRPM dominates due to a misalignment problem, phase readings are essential to distinguish from an imbalance problem. Waveforms typically show repeatable, periodic patterns with one or two clear cycles per shaft revolution.

Looseness (structural & component)

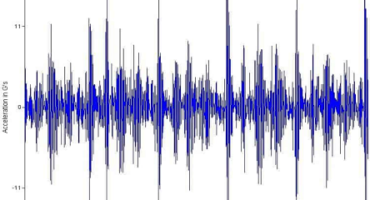

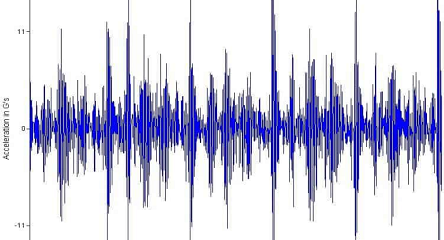

Mechanical looseness occurs when rotating components have been fitted incorrectly. A number of running speed harmonics will dominate spectral data (i.e. 1-10x RPM). In certain instances and stages of deterioration, spectral data may also show sub-harmonic multiplies of 1/2xRPM.

Waveforms typically show high random impacting patterns and, in some instances, the waveform may appear truncated. Structural looseness is the result of loose or distorted machine mountings, foundations, bolts or bedplates. These conditions typically produce a frequency at 1xRPM and/or 2xRPM radially in spectral data (vertical amplitudes may be more predominant), depending upon the type of structural problem. Waveform data is typically periodic, with one or two cycles per shaft revolution.

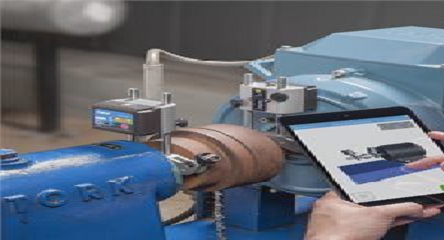

These three conditions can lead to potential machine failure and lost production, but fortunately they are easy enough to correct. However, it’s critical that they are detected early. That’s where vibration monitoring comes in. Vibration analysis allows for the three conditions to be identified at an early stage – enabling maintenance teams to take the corrective action required to prevent components becoming damaged.

What if The Machine like Blower (overhung Fans) have both Unbalance & mis-alignment as well at same time. Phase reading will be bit confusing.

Hi Chiranjeevi

May I ask where you are based? It would make sense the relevant territory manager picks up dialogue with you.

Thanks