Keeping a handle on lubrication is easy, right? All one needs to do is make sure the right lubricant is used in the right amount and at the right time. Not so fast; if only it were that simple.

It has been estimated that 60-90% of all bearing failures are lubrication related1. Bearing failures most often lead to unplanned downtime which can impact production as well as affect all related components around the bearing. Downtime is costly. While the cost varies by incident and by plant, it can add up. Since the most common cause of bearing failure is lubrication related, it’s clear to see that lubrication is serious business. And for the longest time, that “serious business” has been conducted in a way that on its face makes perfect sense—but in fact borders on haphazard.

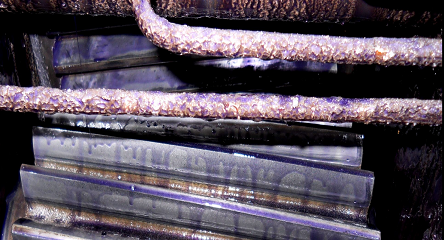

Many technicians, unfortunately, have relied on “preventive”, time-based lubrication alone. That is, every X number of months, the grease gun comes out, and the bearings are lubricated. After all, under-lubrication can be lethal, causing equipment failure, costly repairs and replacements, significant unplanned downtime, and lost profits. But by relying solely on time-based lubrication, or even a combination of planned maintenance and temperature readings to serve as a proxy for lubrication status, one runs the risk of something just as bad, if not worse: over-lubrication. In fact over-lubrication has been reported both anecdotally and in presentations at various conferences to be the primary cause of premature bearing failure.

Relying on time-based, periodic lubrication assumes bearings need to be greased at defined time periods. Often this evolves into a well-intentioned guessing game at best. Adding more lubrication to a bearing that is already adequately greased is a real risk.

By using ultrasound technology (along with standard practices such as removing old grease and replacing it with new), technicians can combine standard time-based maintenance with condition-based, predictive maintenance, gaining in the process both a clearer picture of what’s really going on and better reliability.

How Ultrasound Works

Ultrasonic equipment detects airborne and structure-borne ultrasounds normally inaudible to the human ear and electronically “transposes” them into audible signals that a tech can hear through headphones and view on a display panel as decibel [dB] levels. In some instruments, such as the Ultraprobe 15,000, the received sound can also be viewed on a spectral analysis screen. With this information a trained technician can interpret the bearing condition in order to determine what, if any, corrective action is needed.

Ultrasound technology has many advantages.

- It can be used in virtually any environment;

- Learning to use ultrasound technology is relatively easy;

- The technology is relatively inexpensive;

- Modern ultrasonic equipment makes it easy to track trends and store historical data;

- Ultrasonic technology has proven itself to be extremely reliable in predictive maintenance, saving thousands upon thousands of dollars and hours of lost productivity.

How Ultrasound Produces Better Lubrication Practices

Ultrasonic technology helps the lubrication technician take a lot of the guesswork out of lubrication needs. Ultrasound is a localized signal meaning when a sensing probe is applied to a bearing, it will not be affected by “crosstalk” and allows the technician to hear and monitor the condition of each individual bearing. Ultrasound looks at each individually, much the same way medical ultrasound can detect exactly which artery is clogged or which vein is leaking.

As an example of ultrasound’s efficacy, consider this. A maintenance manager at a large firm reports3 that, since adopting ultrasound technology and practicing ultrasound-assisted, condition-based monitoring rather than “running to put out the fire,” his plant has gone from close to 30 rotating equipment failures per year to zero in three years. But how does ultrasound work, exactly, vis-à-vis lubrication?

The first step is establishing both a baseline decibel level and a sound sample. This is ideally done when moving through a route for the first time by first comparing dB levels and sound qualities of similar bearings. Anomalies will be easily identified. Once established, each bearing can be trended over time for any changes in either amplitude or sound quality.

Generally speaking, when the amplitude of a bearing exceeds 8 dB and there is no difference in the sound quality established at baseline, the bearing needs to be lubricated. To prevent potentially disastrous over-lubrication, the technician will then apply lubrication, a little at a time, until the dB level drops. Many departments set up their “Condition-Based” lubrication programs by incorporating a two- stage approach. The reliability inspector uses a relatively sophisticated ultrasound instrument to monitor and trend bearings. A report of bearings in need of lubrication is produced. The lube tech then uses a specialized ultrasound instrument that alerts the tech when to stop adding grease. (These instruments can be affixed to a regular grease gun or worn in a holster.)

To improve efficiencies, it is a good practice for the technician to note when the equipment was last greased and how much grease was used to calculate roughly how much lubrication is used per week. By using ultrasound to lubricate each and every time, the technician produces historical data that can be used as a guide from previous calculations, helping the department to determine whether the lubrication schedule can be modified, perhaps saving man-hours, and whether the manufacturer’s suggested lubrication amount is accurate (if less is needed, there’s cost-savings potential).

And while most of this discussion has focused on the dangers of under and over-lubrication, ultrasound is just as reliable in picking up other potential bearing failure conditions. The technician, using ultrasound, can hear telltale “grinding” sounds and other anomalies, which are often accompanied by an amplitude increase. With regards to lubrication, the advantage of ultrasound is that it is able to isolate bearings and determine their individual needs, thus reducing the possibility that some bearings are too “dry” and prevent others from over lubrication.

Why You Should Begin Using Ultrasound—Today

It is always a daunting proposition to make a new investment in technology. Will it pay off? Will my staff actually have an easy time using it? Is it a flash in the pan or a truly reliable modality that will stand the test of time?

While more and more plants are using ultrasound and adopting a predictive and proactive rather than reactive mindset, there are still many that are figuratively using crystal balls and outdated methodologies. The end result is poor reliability, unnecessary man-hours, downtime, and lost productivity and profit. While ultrasound can’t cure all reliability ills, it has proven itself—in a plethora of settings—to be a valuable and powerful diagnostic tool that technicians must add to their toolkits.

When it comes to something as important to reliability as lubrication, the question really becomes, “Can you afford not to use ultrasound technology?” Consider the plant that went from close to 30 bearing failures a year before using ultrasound to having no bearing failures for three years once bringing ultrasound into its maintenance arsenal. It’s no coincidence. Ultrasound works.

For more information on ultrasound technology and to access valuable resources, including a sound library, presentations, and articles, visit UE Systems’ website at www.uesystems.com.