MONITORING BEARING WEAR

Ultrasonic inspection and monitoring of bearings is by far the most reliable method for detecting incipient bearing failure and conditions such as lack of lubrication. The ultrasonic warning appears prior to a rise in temperature or an increase in low frequency vibration levels. Ultrasonic inspection of bearings is useful in recognizing:

a. The beginning of fatigue failure.

b. Brinelling of bearing surfaces.

c. Flooding of or lack of lubricant.

In ball bearings, as the metal in the raceway, roller or ball elements begins to fatigue, a subtle deformation begins to occur. This deforming of the metal will produce irregular surfaces, which will cause an increase in the emission of ultrasonic sound waves.

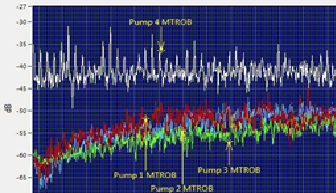

A change in amplitude from the original reading is an indication of incipient bearing failure. When a reading exceeds a baseline reading by 8 dB with no substantial change in the sound quality, it can indicate lack of lubricant. If the reading exceeds a baseline by 12 dB, it can be assumed that the bearing has entered the beginning of the failure mode.

This information was originally discovered through experimentation performed by NASA on ball bearings. In tests performed while monitoring bearings at frequencies ranging from 24 through 50 kHz, they found that the changes in amplitude indicate incipient (the onset of) bearing failure before any other indicators including heat and vibration changes. An ultrasonic system based on detection and analysis of modulations of bearing resonance frequencies can provide subtle detection capability, whereas conventional methods are incapable of detecting very slight faults. As a ball passes over a pit or fault in the race surface, it produces an impact. A structural resonance of one of the bearing components vibrates or “rings” by this repetitive impact. The sound produced is observed as an increase in amplitude in the monitored ultrasonic frequencies of the bearing. The sound quality of these changes can also be heard through headphones.

Brinelling of bearing surfaces will produce a similar increase in amplitude due to the flattening process as the balls get out of round. These flat spots also produce a repetitive ringing that is detected as an increase in amplitude of monitored frequencies.

The ultrasonic frequencies detected by an ultrasonic translator such as the Ultraprobe®, are reproduced as audible sounds. This “heterodyned” signal can greatly assist a user in determining bearing problems. The heterodyned signal may be analyzed through spectral analysis software or by connecting the instrument to a vibration analyzer. When listening, it is recommended that a user become familiar with the sounds of a good bearing.

A good bearing is heard as a rushing or hissing noise. Crackling or rough sounds indicate a bearing in the failure stage. In certain cases a damaged ball can be heard as a clicking sound whereas a high intensity, uniform rough sound may indicate a damaged race or uniform ball damage. Loud rushing sounds similar to the rushing sound of a good bearing only slightly rougher can indicate lack of lubrication. Short duration increases in the sound level with “rough” or “scratchy” components indicate a rolling element hitting a “flat” spot and sliding on the bearing surfaces rather than rotating.

If any of these conditions are detected, more frequent examinations should be scheduled. Data should be collected to note and trend decibel rises. In addition the bearing sound should be analyzed using spectral analysis software or by connecting the ultrasound instrument to a vibration analyzer.