Two Minute Tips

Simplified Vibration Monitoring: ISO 10816-3 Guidelines

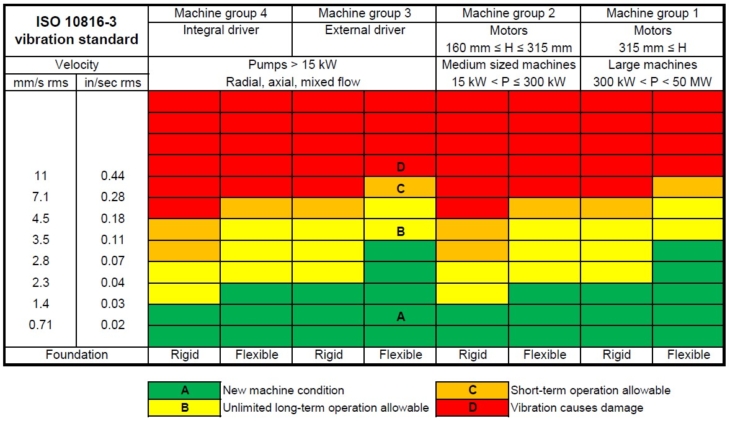

The ISO 10816-3 standard provides criteria for evaluating the vibration of machinery according to measurements taken on non-rotating parts, such as bearings, bearing pedestals, or housings. It serves as a general guideline for determining overall machine condition based on the magnitude of vibration and changes in vibration levels over time. While these aren’t always the only factors that need to be considered when identifying faults, the standard is very useful for performing basic vibration analysis.

ISO 10816-3 specifically applies to machine sets which have a power above 15 kW and operating speeds between 120 and 15,000 RPM. This category includes common industrial motors, pumps, generators, rotary compressors, blowers and fans, and several types of turbines. Of course, some machines have power requirements or speeds outside the scope of the standard; however, the majority of the machines you’re likely to encounter can be evaluated according to these guidelines.

By taking a few measurements in terms of vibration velocity and using the chart shown above, it’s possible to make good use of vibration data no matter your level of expertise. Referencing the ISO 10816-3 guidelines helps you quickly identify problem machines and perform targeted maintenance before more serious damage occurs. It’s a valuable, easy-to-use tool for more effective condition-based monitoring.

Why the motors have been grouped based on height ?

The table is very nice, colorful and informative. However, the columns seem to be erroneous. The rigid and flexible columns should be exchanged. This can be confirmed from the standard ISO 10816-3. I hope you can correct this table because it has been used in industry and in this current form it generates confusion. My best regards

Vibration standard shows Velocity RMS (mm/sec) for the equipment? Then what about acceleration rms? any ISO standard for acceleration rms?

No, there are no equivalent ISO guidelines for monitoring vibration in terms of acceleration.

Warning to any readers, there is an error in this chart, the foundation types are backwards on the chart. A flexible foundation will have the higher vibration tolerance than the rigid foundation. Check the ISO standard or look for a chart elsewhere.

I agree with you. This chart is wrong. The author must correct the titles of Foundation types.

Al B, thank you so much for bringing this to our attention! We have updated the chart and it should now be correct.

Is there any ISO standard for no-load equipments

If yes, please share the chart for our ready reference

what is the acceptable vibration of 15 kw electric motor with high pressure compressor