Why does our equipment fail? Because we kill it. I visit plants regularly, and I see numerous examples of poor lubricant storage.

If you had to grab a drum of oil in your plant, which one would you choose? Most people would choose the drum closest to them. But the drum in the picture above is 18 years old and was not used yet because it was never the closest drum. Lubricants have a shelf life.

Remember, new oil coming into a plant is not usually clean. It will meet the viscosity requirements but not the ISO cleanliness targets. And when we store lubricants in unclean environments, we get contamination. And those tiny contaminants that get into clearances destroy our machines.

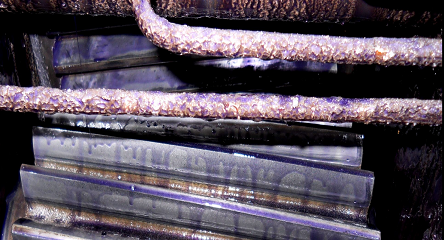

These are 5 gallon pails of grease, and there are a few big problems here. First, the product dates are from 1985 and 1995 (the photos were taken in 2018). Second, they are plastic.

Another problem is that people put oil into open containers for dispensing, and the oil becomes contaminated. If I put the oil into an asset, that asset will not reach its design life. Over the last two years, I’ve inspected around 1,000 containers, and I only saw three that were clean. I saw visible debris in most of them.

I also saw dirty, damaged drums stored outside. I saw plastic drums that had swollen, meaning the integrity of the oil had been compromised. Those drums were four years old, and the plant was about to use that oil during a turnaround.