Gearbox defects can be identified with a quite high accuracy using vibration analysis. This is because the fact the most common defect frequencies are the fundamental Gear Mesh Frequency (GMF) and its harmonics (such 2x GMF, 3x GMF) which can easily be detected. Before looking at gear defects, it is necessary to understand how defect frequencies such as GMF are calculated. Gear Mesh Frequency is the product of the number of tooth on the gear multiplied by the running speed of the gear. The formula that is used for this is as follows:

GMF = No. Teeth x RPM

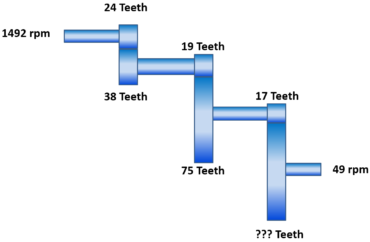

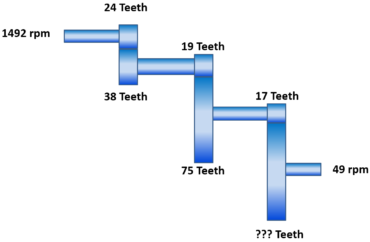

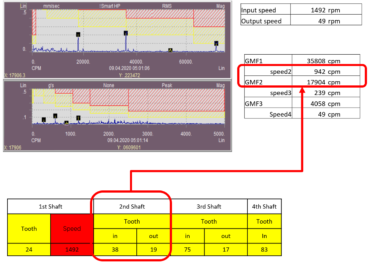

To understand it better let’s look at an example and try to calculate how many teeth are on the output gear if the output speed is 49 rpm.

The calculation required is not rocket science and is as follow:

Speed1 (input) = 1492 CPM

GMF = 24 x 1492 = 35 808 CPM

Speed2 = 35 808 ÷ 38 = 942,32 CPM

GMF2 = 19 x 942,32 = 17 904,08 CPM

Speed3 = 17 904,08 ÷ 75 = 238,72 CPM

GMF3 = 17 x 238,72 = 4 058,24 CPM

Then:

No. Teeth on Gear = GMF ÷ RPM

Speed4 (output) = 49 CPM

GMF3 = 4 058,24 CPM

??? Teeth = 4 058,24 ÷ 49 = 82,8212 ~ 83 Teeth

As an example, the fundamental Gear Mesh Frequency (1x GMF) for a gear that has 24 teeth which are running at a speed of 1492 rpm will be 24 x 1492 = 35 808 cpm. The first (2x GMF) and second (3x GMF) harmonics of this would therefore be 2x 35 808 = 71 616 cpm and 3x 35 808 = 107 424 cpm.

Since it is impossible to manufacture perfect gears (tooth profiles, concentricity, meshing characteristics), it is very common to identify some gear-related vibration on almost every gear drive system. However, if the vibration at 1x GMF and its harmonics are considered excessive when compared to normal levels or industry standards, an analysis should be carried out to identify the cause of the problem. This is not only to avoid a breakdown of the gearbox but will increase the service life as well.

Significant gear problems such as wear, misalignment, or looseness may not cause a significant increase in the amplitude at 1x GMF. In many cases, these problems cause a higher amplitude increase at harmonics of the gear mesh, such as 2x GMF or 3x GMF while no change or very little in the amplitude of the fundamental gear frequency. The reason that gear defects may be detected at harmonics of GMF is explained by the fact that tooth engagement can result in several impacts or force-exciting events. This is also why it is recommended that when a gear analysis is to carried out, the frequency for the spectrum should be set at least 3.25x expected to see Gear Mesh Frequency.

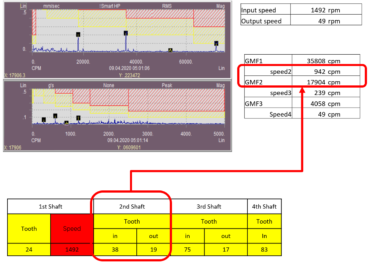

What also important, the gear defects not only cause vibration at GMF and its harmonics – these frequencies will often be accompanied by sidebands of the rotating speed of the defective gear. Based on given example where input speed was 1492 rpm and the number of teeth was 24, this gave a gear mesh frequency of 35 808 cpm and the intermediate shaft speed was calculated as being 942,32 rpm. Therefore, if there was a defect on the input gear, there would be sidebands spaced at 1492 cpm above and below the gear mesh of 35 808. On the other hand, if the defect was on the 38 teeth gear, the sidebands would be spaced at 942 cpm above and below the gear mesh. Lastly, if there was a defect on both gears, then there would be two families of sidebands around the gear mesh one would be at 1492 cpm and the other would be at 942 cpm. Stated simply, the spacing of the sidebands can pinpoint the gear that has the defect.

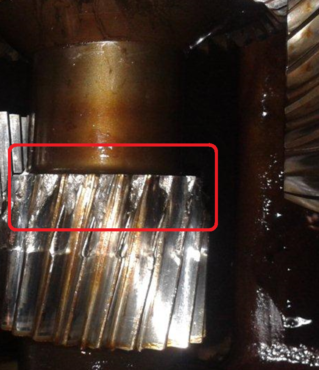

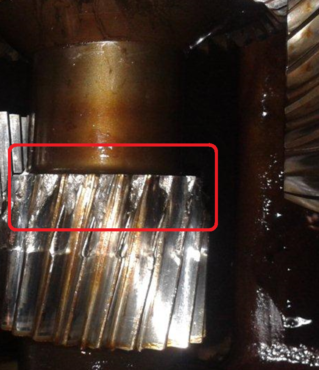

To better understand this part following the same given example see the real defect on the 19 teeth gear, where sidebands are spaced at 942 cpm above and below the gear mesh of 17 904. 1x GMF2 and its harmonics (2x GMF2, 3x GMF2, 4x GMF2) are seen.

2nd shaft gear (19 teeth) condition after machine stoppage:

Analyzing gearboxes you have always be aware that other mechanical problems such as distortion of the gear casing or bearing problems can also result in higher than normal amplitudes at Gear Mesh Frequency and its harmonics. Therefore, when a significant change in the amplitude of gear vibration has detected, the analyst should check for other mechanical problems that may be the cause of the problem before simply condemning the gears themselves.

Moreover, always when some doubts the Time Waveform usage, which can support you with analysis and help to identify the real defect is highly recommended.

Very good explanation about GMF and its harmonics.

Thank you for your kind words Arvind Kumar Gupta

Thank you very much. The explanation on the calculation of GMF is very well done.

Thank you for your kind words Yakeu Happi

Sir, Can you explain with some case study about Gear Box Bearing problems and defects-1st Stage to Last Stage Bearing Defects.Your GMF explanation is very good. I have aiready done GMF detection and analysed Gear Defects in 3 Stage Gear Box before six years in my previous plant.In my previous plant Paper m/c main drive gear box and Dryer Drive gear boxes, there were lots more gear box defects such input coupling looseness, input misallignments, some foundation problems, also bearing defects in addition to Gear Defects, which i analysed. But , i want to learn from you some more techniques… Read more »

Sir, Can you explain with some case study about Gear Box Bearing problems and defects-from 1st Stage to Last Stage Bearing Defects.Your GMF explanation is very good. I have aiready done GMF detection and analysed Gear Defects in 3 Stage Gear Box before six years in my previous plant.In my previous plant Paper m/c main drive gear box and Dryer Drive gear boxes, there were lots more gear box defects such input coupling looseness, input misallignments, some foundation problems, also bearing defects in addition to Gear Defects, which i analysed. But , i want to learn from you some more… Read more »