Lubrication

Machinery Lubrication Challenges in Covid-19 Times

The current global pandemic situation has thrown many challenges in every sector including Machinery lubrication activities. Subbu discusses how to be prepared for continued reliability of the equipment in lubrication activities..

- KNV Subrahmanyam

- Single Peak Lube Technologies

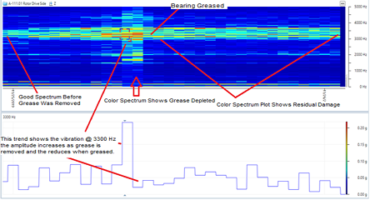

Detecting Lack of Lubrication with Wireless Vibration Sensors

Why wireless sensor Fmax is Critical. Lack of lubrication is a major cause of bearing damage & bearing failure. Therefore, it is critical for vibration sensors to be able to detect the higher frequency vibration resulting from lack of lubrication, which is generally far above 1kHz..

- Mike Olszewski

- Reliability Concepts

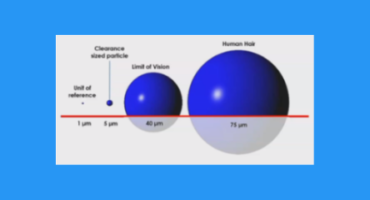

Lubrication: Contamination Control

How clean are the lubricants at your plant? Are you sure? Geoff Manley gives some tips on contamination control…

- Geoff Manley

- Lubrication Engineers Pty Ltd

Storing and Dispensing Lubricants: Some Do’s and Don’ts

Due to lubricants’ high impact on reliability, a step change must be made in the way lubricants are viewed. Let’s look at some pictures of what to do and what not to do when it comes to storing and dispensing…

- Geoff Manley

- Lubrication Engineers Pty Ltd

Lubrication: The All-Important Blood of Your Machines

When it comes to lubrication, some people assume it’s “just oil” or “just grease,” and they choose the cheapest one. This needs to change. Lubrication is not a commodity…

- Geoff Manley

- Lubrication Engineers Pty Ltd

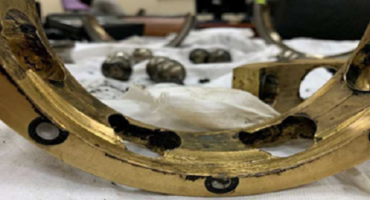

Poor Lubrication – Brass Cages Are Boon

An antifriction bearing generally has 4 major components. In this case study we will discuss how brass cages are better in a highly dusty & contaminated poor lubrication condition...

- Akhil jeet Rathore

- Indorama Petrochemicals & Fertilizers

The Journey to World-Class Storage & Handling – Basic American Foods

When Scott Fischer, Maintenance Manager, joined Basic American Foods, he recognized that the Blackfoot Basic American Foods plant was in need of a dedicated lubricant storage and handling process and products to support his reliability program goals.

- Mark Barnes

- Des-Case

Cracking the ISO Code to Lubricant Cleanliness

So what does it really mean to increase lubricant cleanliness? We read various articles and textbooks that talk about how increasing the cleanliness of an in-service oil will increase the life of a component and the lubricant, but how do we make that happen...

- Mark Barnes

- Des-Case

How to Keep Lubricants Clean, Cool & Dry

What are some best practices for lubrication cleanliness at your plant? In this quick Two Minute Tip you will see a few ides for contamination control.

- Rob Kalwarowsky

- Rob's Reliability

- 1

- …

- 6

- 7

- 8

- 9

- 10

- …

- 14