Lubrication

Aluminum Complex Thickener Greases

Lubricant has the power to increase equipment uptime and enhance bottom line profitability.

- John Sander

- Lubrication Engineers

Meet MOBIUS CONNECT Ambassador: Ed Duda

Ed Duda is a Technical Consultant for Des-Case Corporation, Goodlettsville (Nashville), TN. Prior to joining Des-Case, Ed was a Process Engineer for Freeport-McMoRan Inc. Ed has worked in several roles including plant leadership focused on operational excellence. Now he is happy of being part of our team as a Brand Ambassador and...

- Ed Duda

- Des-Case

A Holistic View of Fluid Analysis

This fluid analysis learning path includes 8 short units that include details on various types of fluid testing as well as features of a successful fluid analysis program including effective data management and integration, taking a representative sample, and other value-add services available – so you can start saving more of your equipment.

- Julio Acosta

- POLARIS Laboratories

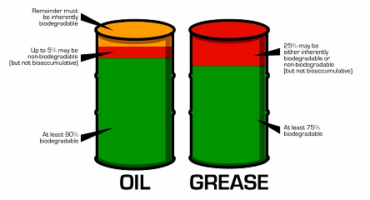

Can Lubrication Programs Be Green?

The traditional environmental lubricant has been one that is either biodegradable or is formulated from biobased materials. From a more holistic standpoint, lubrication programs have been environmentally sustainable in other ways for years.

- John Sander

- Lubrication Engineers

Machinery Lubrication Challenges in Covid-19 Times

The current global pandemic situation has thrown many challenges in every sector including Machinery lubrication activities. Subbu discusses how to be prepared for continued reliability of the equipment in lubrication activities..

- KNV Subrahmanyam

- Single Peak Lube Technologies

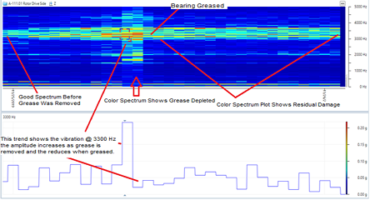

Detecting Lack of Lubrication with Wireless Vibration Sensors

Why wireless sensor Fmax is Critical. Lack of lubrication is a major cause of bearing damage & bearing failure. Therefore, it is critical for vibration sensors to be able to detect the higher frequency vibration resulting from lack of lubrication, which is generally far above 1kHz..

- Mike Olszewski

- Reliability Concepts

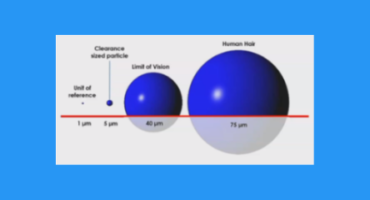

Lubrication: Contamination Control

How clean are the lubricants at your plant? Are you sure? Geoff Manley gives some tips on contamination control…

- Geoff Manley

- Lubrication Engineers Pty Ltd

Storing and Dispensing Lubricants: Some Do’s and Don’ts

Due to lubricants’ high impact on reliability, a step change must be made in the way lubricants are viewed. Let’s look at some pictures of what to do and what not to do when it comes to storing and dispensing…

- Geoff Manley

- Lubrication Engineers Pty Ltd

Lubrication: The All-Important Blood of Your Machines

When it comes to lubrication, some people assume it’s “just oil” or “just grease,” and they choose the cheapest one. This needs to change. Lubrication is not a commodity…

- Geoff Manley

- Lubrication Engineers Pty Ltd

- 1

- …

- 4

- 5

- 6

- 7

- 8

- …

- 13