Lubrication

Maximize Open Gear Life

Large open gears on grinding and pulverizing mills present significant lubrication challenges due to the high-load, heavy-shock nature of the applications and constant exposure to harsh

environmental conditions...

- John Sander

- Lubrication Engineers

Environmental Impact of Wire Rope Lubrication

How do I minimize lubricant impact on the environment while protecting wire rope?

- John Sander

- Lubrication Engineers

Wire Rope Lubricants

In this two minute tip, we will review the three principal functions of wire rope lubricants...

- John Sander

- Lubrication Engineers

Putting the Simple Back into Viscosity

Simply stated, viscosity is defined as the internal resistance of a fluid to flow. That doesn’t sound too difficult, does it?

- John Sander

- Lubrication Engineers

Eliminate Gearbox Suffering Points

The number one cause of failure in any mechanical application contamination. Every industrial plant has a sizable investment in both its equipment...

- Patrick Loe

- Lubrication Engineers, Inc.

What are the Most Common Lubrication Issues You See?

In this interview with CBM CONNECT, Rodney discusses the top lubrication issues that he's seen, and what the best resolutions are...

- Rodney Fitzpatrick

- Lubrication Engineers Pty Ltd, Australia

The Role of Lubrication in Machinery Reliability

Less than 0.5% of a plant's maintenance budget is spent purchasing lubricants, but the downstream effects of poor lubrication can impact...

- Mark Barnes

- Des-Case

Guide to Electrical Inspection with Ultrasound Technology

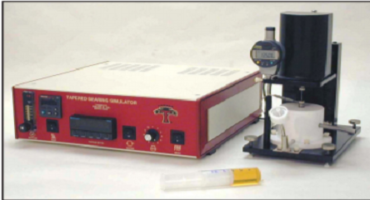

The Good, Better, and the Best approaches to lubricating bearings. Ultimately, are condition based approach using ultrasound to let the lubricator know when they have applied enough grease...

- Adrian Messer

- UE Systems

Setting Up a Lube Room

CBM CONNECT spoke with Clay to see what steps are involved in setting up a lube room in your facility...

- Clay Allen

- Mosaic

- 1

- …

- 8

- 9

- 10

- 11

- 12

- 13