Alignment + Balancing

Meet MOBIUS CONNECT Ambassador: Rao Vamsidhar

Rao Vamsidhar is a Maintenance Manager having a rich experience of 20 years in the rotating machinery field. He has begun his career as a Management Trainee in Power Engineering Maintenance department in Visakhapatnam Steel Plant, India in 1998 and successfully progressed and elevated to the position of Assistant General Manager in 2016. Today he talks about his career, plans as a MOBIUS CONNECT Brand Ambassador and...

- RAO VAMSIDHAR

- VIZAG STEEL

Preview the 2021 SMRP Annual Conference!

The Society for Maintenance and Reliability Professionals (SMRP) is preparing to welcome attendees for its 29th Annual Conference. Hear from SMRP Executive Director Erin Erickson about what's in store for attendees at this year's event.

- SMRP

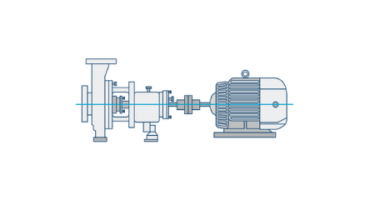

3D Laser Measurements To Modernize Machinery Alignment

Accurate placement and precise shaft alignment of machinery components is key for optimal and efficient operation. Although none of the traditional methods are bad or inadequate if carried out correctly, they can be complex and time consuming the least..

- Geert van Rijswick

- van Geffen AMS BV

Phase Simulator

The simulator of measuring system (Lead Phase or Lag Phase), phase convention (Rotating Scale or Fixed Scale) and scale direction (Contrary to Rotation or Same of Rotation), shows, during rotation, for the first turn the tachometer event...

- Jose Mendez Adriani

- Central University of Venezuela

Detecting and Diagnosing Misalignment in a System

Next-generation sensors based on MEMS technology, combined with advanced algorithms for diagnostic and prognostic applications, expand opportunities to measure a variety of machines and improve the ability to effectively monitor equipment, improve uptime, enhance process quality, and increase throughput. This 5 minute fact reviews misalignments and their characteristics to provide insights into some of the key system requirements that must be considered when developing a condition-based monitoring solution.

- Pete Sopcik

- Analog Devices, Inc

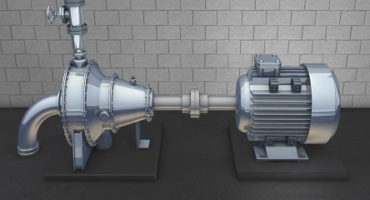

How Long Will Rotating Machinery Stay Accurately Aligned?

We used to assume that once the equipment is installed and aligned, it will remain in the same position forever. But this is not always the case..

- Roman Megela

- Easy-Laser

Sleeve-Bearing Monitoring at Slow-Variable Speed Using FDS Technology

Sleeve bearings are typically found in our most critical assets. There often is not adequate instrumentation on them, and they are difficult to monitor...

- Dries Van Loon

- NanoPrecise

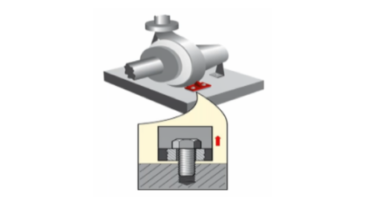

Four Ways Soft Foot Affects Machinery

Soft foot is a condition that occurs when rotating machinery is positioned incorrectly ─ specifically, when one or more of the “feet” of a machine’s base, frame, or soleplate are not making the same point contact as the others...

How to Cut Your Time in Measuring For Misalignment Issues

PRUFTECHNIK sensALIGN technology upgrades ancient angularity and offset measurement practices..

- 1

- 2

- 3

- 4

- 5

- …

- 11