Case Studies and Stories

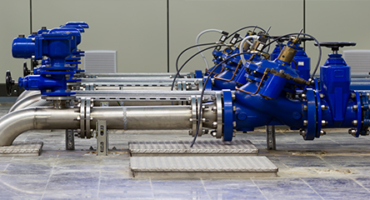

Electrical Signature Analysis Performed on Vertical Turbine Pump Motors in Municipal Application

Originally put into operation in 1999, Pump Station P-19A supplies drinking water to the City of Henderson, which is the second largest city in Nevada. In January 2015, Motor 5 exhibited signs of overheating...

- Bill Kruger

- ALL-TEST Pro

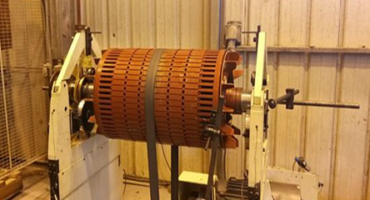

Induction Motor Rotor Dynamic Balancing Case Study

On this occasion a rewinding job was executed by a local service company on a 3000 hp induction motor. After evaluating the machinery, the CBM team recommended that a dynamic balancing job was needed to reduce vibration levels to optimum condition…

- Alejandro Poveda

- Repsol

HD Technologies Case Study: Ball Mill Bearing Damage

This case study describes bearing damage detected through online measurements taken from a ball mill at the flotation plant of Asarel Medet AD in Bulgaria. At the beginning, the SPM HD trend had varying shock pulse levels...

- Dobromir Dobrev

- SPM Instrument Bulgaria EOOD

Hear Failure from Miles Away

Experienced maintenance professionals can understand if a machine is healthy or not by walking up to it and using their senses – hearing, touch, smell, and sight. But this skill doesn’t scale when there are more plants than experts. This case study – a TechINSIGHT – shows how IoT maintenance solutions are helping machine analysts be in multiple places at once...

- Brett Burger

- National Instruments

Duke Energy Takes Advantage of IIoT for Predictive Maintenance Applications

This case study investigates Duke Energy’s quest to replace its monthly, manual data collection practices with daily, remote data collection and monitoring.

- Alex West

- IHS Markit

B3 Electric Improves Safety, Builds Reputation, Saves Time

An electric service provider benefited from including condition-based maintenance principles, tools, and software into their maintenance program. Learn more by reading the two-minute tip today...

- Gregory Perry

- Fluke Corporation

Automotive Manufacturer Compares In-House Third-Party Motor Testing. Guess Which One Saved the Most Time and Money?

Catching motor problems before they fail saves your plant headaches, not to mention a ton of money they would have lost through unplanned shutdowns. View the lessons learned by manufacturers who needed reliability programs...

HD Technologies: Press Roll Bearing Damage Detection

At a Romanian paper mill called Vrancart S.A., the online system Intellinova Compact with HD condition monitoring technology is installed to monitor the press section of paper machine K25. This case study involves the detection of bearing damage on one of the press rolls, showing the development of the damage over a period of about six weeks…

- Dobromir Dobrev

- SPM Instrument Bulgaria EOOD

Save Energy in Steam and Condensate Systems

The oldest paper mill still operating in Germany detects defective steam traps with digital ultrasonic testing technology…

- Stephanie Moczigemba

- SONOTEC GmbH

- 1

- …

- 3

- 4

- 5

- 6

- 7

- …

- 9