Five Minute Facts

4-20 mA vs. IEPE Vibration Sensors for Process Control Systems

With process control systems, it’s simple (and smart) to incorporate vibration data into an existing monitoring program. Either loop-powered 4-20 mA sensors, which output a direct 4-20 mA signal or IEPE sensors, which output dynamic data that can be converted into an acceptable process signal, can be used. The best choice depends on the machinery being monitored, the specific faults of concern for the machine, and the existing infrastructure and resources available. We’ll address the different types of vibration sensors, some of the factors that should be taken into consideration when choosing a sensor, and the options available for a vibration monitoring setup using either sensor type.

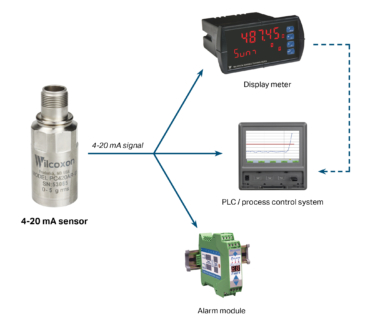

The most common option in plants with PLC/DCS/SCADA systems is using a 4-20 mA vibration sensor which outputs directly to the control system – just like any of the temperature, pressure, or flow sensors often already in place. 4-20 mA sensors provide continuous trend data, making it easy to track changes in overall vibration levels. This approach is the most cost-effective option for implementing vibration monitoring, at a lower relative cost per data point than using standard accelerometers.

For applications requiring visual-only alarm indication or direct access to the data, a 4-20 mA sensor can be used in combination with an alarm module or a display meter. Alarm modules are a good choice for plants without control systems in place. Display meters can be used similarly, and can also be programmed to output to a control system; many models accept other process inputs as well.

For most machinery, 4-20 mA trend data is sufficient for understanding machine condition. The majority of faults on rotating machines are in the mid-frequency range and appear as rising vibration levels over time. Imbalance, misalignment, and looseness – some of the most common causes of machine failure – tend to have fault frequencies between 120-60,000 CPM and can generally be detected with this method. The downside is that dynamic vibration data isn’t available, meaning portable data collection and fault analysis can’t be performed. In addition, trend data may not pick up signs of other impending faults outside of the frequency range.

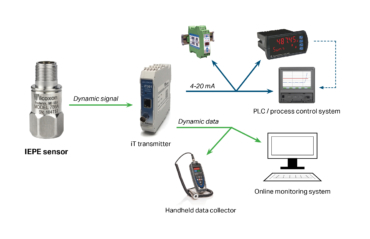

Outside of the mid-frequency range, an IEPE sensor can be a better option than a 4-20 mA sensor. In this setup, an accelerometer or velocity transducer outputs to a vibration transmitter, which conditions the dynamic data before sending a 4-20 mA signal to the control system. The transmitter can also output to a display meter or alarm module.

This approach also provides continuous trend data, with the added benefit of retaining dynamic vibration data. The dynamic data can be analyzed to identify faults which caused a rise in the 4-20 mA overall signal, ensuring a more accurate and faster diagnosis of the exact issue. It does come at a higher upfront cost and is advised for applications that require access to dynamic data – portable data collection, or equipment on which you expect to measure very low or very high frequencies. IEPE sensors are also available with a wider variety of hazardous location certifications, which may make them more suitable for certain applications.

To identify pump cavitation, bearing fatigue, gear mesh faults, or impacts from loose components, it helps to look at more than just the machine’s overall vibration level. In these cases, an IEPE sensor should be used.

For example, on critical pumps where cavitation is a concern, it’s desirable to have the detailed information from an IEPE sensor available for analysis because the earliest signs of cavitation won’t be captured in the overall trend data. In this case, using a low sensitivity/high frequency accelerometer in combination with a vibration transmitter will help you detect cavitation earlier and address the issue before the equipment fails.

Bearing wear also commonly occurs at high frequencies (4x-20x running speed) with low vibration amplitudes, and critical bearings are most effectively monitored with IEPE sensors. On slow speed machinery, a low frequency accelerometer will provide more useful low frequency information than a 4-20 mA sensor.

A 4-20 mA sensor that outputs to an alarm module, display meter, or the control system:

- Has a lower setup cost

- Provides simple trend data for continuous monitoring

- Is easily incorporated into existing plant infrastructure

- Is best used for general machine monitoring – frequencies between 120-60,000 CPM (2-10,000 Hz)

An IEPE sensor combined with a vibration transmitter:

- Has a higher initial cost

- Enables access to dynamic data for portable data collection or detailed analysis

- Provides 24/7 trend data for continuous monitoring

- Wider sensor selection for a more varied range of applications

- Is best used for detecting high frequency faults, monitoring slow speed machines, or route-based data collection

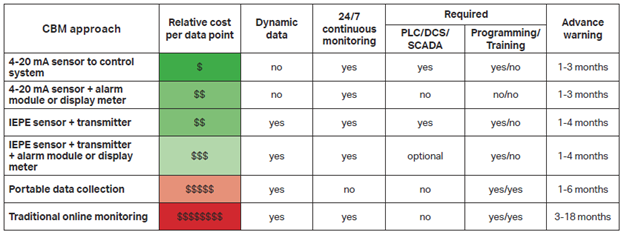

To help you select the best option for your requirements and budget, the table below outlines several ways to add vibration data to a condition-based monitoring program.