Any statement regarding the service life of gear oils should include information regarding operating, environmental and mechanical conditions of the equipment. Even in the best of situations, gear and circulating oils will not last indefinitely.

From the standpoint of both service and economy, gear oil should be removed and replaced with fresh lubricant when the oil has deteriorated or when the oil has become contaminated.

When severe operating conditions are present, change intervals may need to be shortened.

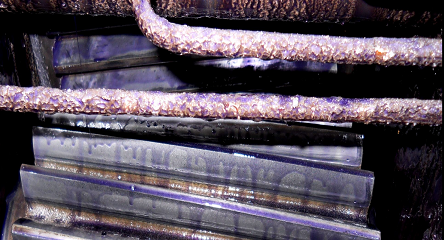

Examples of severe gearbox operating conditions are:

- Rapid fluctuations in operating temperatures, high speeds, heavy loads or shock loads

- Any operating environment that causes condensation inside the gear case or oil reservoir, resulting in formation of sludge and causing the gear oil to foam*

- Operation in moist or dusty environments or where chemical fumes are present; in such instances, set change intervals accordingly*

*Desiccant breathers with particle traps will greatly reduce these problems.