Resonance Definition

Resonance is a phenomenon that amplifies a vibration. It occurs when a vibration is transmitted to another object whose natural frequency is the same or very close to that of the source.

Examples

Look at the example of a pendulum.

When I push the pendulum, the energy I apply is not immediately lost. Instead, it remains in the form of movement of the pendulum that is gradually lost. If I push it once in each cycle, that new energy accumulates to the energy that was already in the pendulum in the form of movement, just like when you push your toddler on the swing.

Note the opposite case. When I stimulate the pendulum to a different frequency, I will be fighting against the energy that was already accumulated, therefore, no energy will be added to the existing one.

Something very similar happens in rotating machines. When the speed of a motor is close to its natural frequency, it will resonate. Thus, any vibration due to unbalance, however small, will be amplified. In this way, small masses will cause surprising changes in vibration.

Finally, as if all this were not enough, the vibration of a machine does not behave linearly. The amount of vibration produces small structural changes that momentarily modify the natural frequency as well as the damping, causing it to behave slightly differently at different vibration levels. All of this makes balancing complicated.

Learn how to Diagnose Resonance.

Resonance is easy to diagnose; however, it is important to know how to detect it. A machine, during operation, will gradually increase its vibration, resonance will cause the vibration to suddenly increase when the machine reaches its final speed. The same happens on “cool down”, when the RPM gains a small distance from the natural frequency, the vibration immediately decreases.

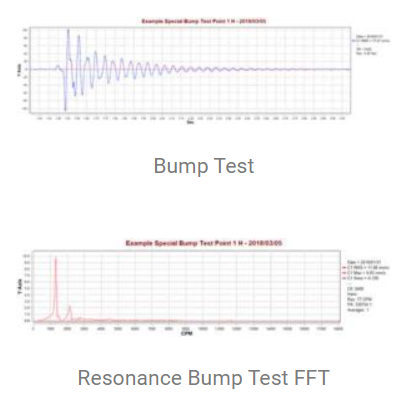

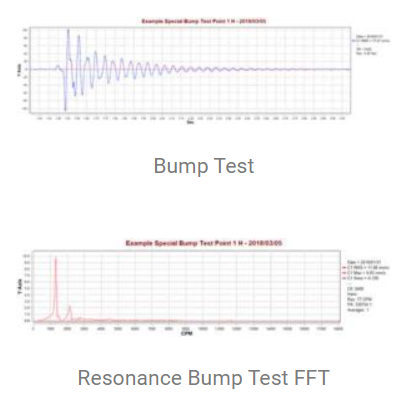

Bump Test | Natural Frequency

In the “Bump Test” the recording of the vibration is made after hitting the machine. In the spectrum you will then observe the resonant frequencies of the structure. You can confirm the diagnosis within 95% certainty, in case any of those frequencies is close to the rotation speed (Be sure you know with certainty the speed of rotation). Usually this study is enough to diagnose the resonance, however there is another test in case of needing a confirmatory test.

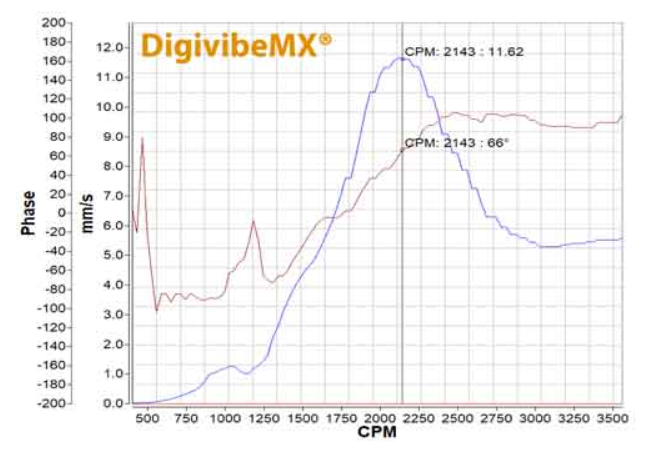

Bode Plot in Resonance analysis

Bode Diagram is a Coast Down or Run-Up test that integrates vibration and RPM measured by a tachometer or RPM sensor. This test calculates the FFT and the phase related to the RPM signal at each time interval. This test confirms the resonance by observing a change in the 180º phase between the moments before and after crossing the suspected frequency

Correct Resonance

The good news is that the resonance phenomenon is easy to correct. Simply move the natural frequency away from the excitation frequency.

Correction actions are divided in 2:

Modify the Natural Frequency

You can increase the natural frequency by increasing the rigidity of the structure. Make sure to reinforce the structure the same direction of the natural frequency. This is the most common solution to avoid changing the performance of the machine.

You can also decrease the natural frequency by removing rigidity to the structure. It is not as common, but it is equally possible and effective, provided that the performance of the machine is not compromised.

You can decrease the natural frequency by adding mass. Changing the mass of a structure will change its natural frequency and therefore also move it away from its rotation speed.

You can also increase the natural frequency by removing mass. This is the least frequent action, but it is equally effective.

Modify the RPM to move them away from the Natural Frequency

If a drive controls the motor speed, then change the RPM. It is the simple thing to do. In case having a belt/pulleys transmission, changing the diameter of the pulley could be the solution. In any case, it is important to verify that the performance of the machine remains enough for its functions, and of course that the current consumption does not exceed manufacturer´s recommendation.

(To read the full article click here)