Many times, metals come with well-cut sizes and shapes. But how does it happen? Cutting metals into desired properties is called machining. Machining refers to the cutting, shaping, and removing of materials from a workpiece with the help of a machining tool.

During the machining process, the heat begins rising at the cutting zone. The heat comes from the friction between the rake surface of the cutting tool and the chips. Continuous machining increases heat around the cutting zone, affecting the metalwork and the cutting machine.

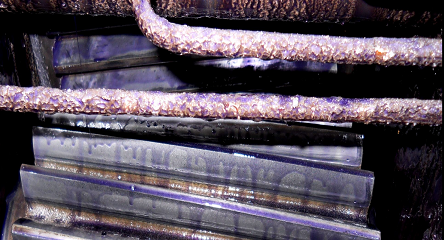

Machining heat leads to the tear and wear of the cutting tool. In addition, it burns the machined surface and results in poor surface quality. That makes it necessary to maintain the cutting temperature within the applicable limits to produce quality work and protect the cutting tool.

Cutting fluids are critical when using a vertical milling machine to control the cutting temperature. This article offers detailed information on what coolants and lubricants are and the essential differences between the two cutting fluids.

Meaning of Lubricants and Coolant in Machining

Lubricants

Lubricants are substances applied at the interface between a cutting edge of a machining tool and the chip to prevent the chip from welding to the tool. A lubricant reduces friction between a surface and another when they come into contact. The reduction in friction minimizes heat production as the surfaces move.

Increased friction between moving parts of the machining tool damages a machine. So, a lubricant also lowers friction among the moving parts, increasing the efficiency of a cutting tool. A lubricant is beneficial in a lathe machine or vertical milling machine.

Coolants

Coolants are substances applied to reduce the heat generated over a long time during the metal-cutting process. A coolant keeps the cutting machine cool, the chips, and the cut pieces.

Using lubricants in machining tools gives them longer life through cooling. Coolants can be delivered through a spindle coolant system to the cutting interface.

The Key Differences Between Lubricants and Coolants

Purpose Differences Between Machining Coolants and Lubricants

During the metal-cutting process, much heat is produced at the cutting zone. So, a coolant helps to reduce temperatures at the cutting zone by taking away the heat. Reducing heat generated during machining protects the cutting tool and enhances the quality of the cut.

The coolants only control the heat generated and don’t affect the rate of heat production during the machining process. Besides preventing heat build-up between the workpiece and the cutting zone, a coolant offers lubrication, reducing friction between the cutting tool and chip removal.

On the other hand, a lubricant reduces friction between the rake surface of chips and the cutting machine, reducing the heat production rate. Lubricants introduce another element into a friction equation, transferring heat away from points of friction. So, the lubricant doesn’t affect the heat generated in machining before its application.

Another role of a lubricant is the reduction of part wear in a machining tool. The parts of a cutting tool move against each other, making the contact points erode. Therefore, applying a lubricant offer a buffer against the raw tear of the machining tool.

A lubricant also draws cutting debris and external contaminants away from the machining tool. Debris from the metal-cutting process causes friction and erosion. So, using lubricants moves the debris and contaminants away from a machining way, which offers protection.

Differences in Composition of Machining Coolants and Lubricants

Machining coolants are made of water and soluble oil. Water-soluble cutting fluid offers the best choice of coolant for general machining. Mixing water with water-soluble oil forms emulsions, which enhances cooling. The high specific heat capacity makes water a suitable coolant.

When it comes to lubricants, they don’t have soluble oil and water. Instead, a machining lubricant is made up of petroleum-based mineral oils. Water has low lubricity and does not fit as a good lubricant.

Protection Difference Between Coolants and Lubricants

A coolant protects the cutting tool and extends its life. On the other hand, lubricants protect the machining tool’s moving parts and extend their lives. Coolants remove heat generated by work and the cutting tool, while lubricants lower friction between the mobile part of a machining tool, reducing tear and wear and giving the mobile parts longer life.

Oxidation Differences Between Coolants and Lubricants

Oxidation in machining affects the quality of the cut. When oxidation occurs, the thin oxide film is deposited, which covers the cut and affects subsequent coating. The presence of water in coolants leads to oxidation, affecting the quality of metalwork.

On the other hand, no oxidation takes place with lubricants during machining. Lubricants do not contain water, which prevents oxidation from occurring.

Property Differences Between Coolants and Lubricants

The soluble oil, water, and air substances in coolants are in a gaseous and liquid state. Coolants have low viscosity and high thermal capacity.

On the other hand, graphite, grease, and oil substances in lubricants are in liquid, solid, and semi-solid states. The lubricants have a low freezing point and high boiling point. A high viscosity index is another property of a lubricant.

Conclusion

Both coolants and lubricants offer protection to a cutting tool. Coolants take away the heat generated during the machining process, which increases the life of the cutting tool.

Lubricants, on the other hand, reduce friction between two mobile parts during machining, which prevents raw tears. The coolants are made of soluble oil and water. However, lubricants contain petroleum-based oil. While water in coolants allows oxidation, lubricants lack water.