Earlier, general-purpose lubricants used to be enough to meet the lubricating needs of a given application. In the past, a person’s experience and expertise were the primary factors in choosing a lubricant.

But due to the surging demand for modern industrial settings to run quicker, longer, and harder, this strategy is no longer practical. Today, extreme criteria tailored to each use case are what modern lubricants must meet.

This article’s objective is to address some of the most often discussed considerations about lubrication selection so that you may pick the best lubricant for your needs rather than blindly opting for the inexpensive or quickest option.

Top 5 Vital Factors to Consider While Selecting the Ideal Lubricant

1. Functions of the Lubricant

Lubricants serve a variety of purposes, including but not limited to-

- Friction- They minimize heat buildup and energy utilization.

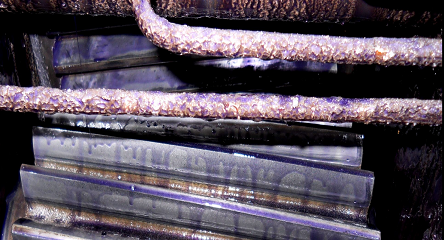

- Corrosion- They protect surfaces against corrosive elements.

- Wear- They minimize corrosive and mechanical wear.

- Temperature regulation- They can soak and transfer excessive heat.

- Contamination- They transmit particulates and other impurities to separators and filters.

It implies that the lubricant you select will depend on the specific demands of your application. So, select lubricants that have informative labels detailing their intended uses and conditions.

2. Practicality And Ease of Operation

There is no one standard method for using lubricants. How you apply it will be determined by the equipment. For instance, an aerosol lubricant might be all that’s needed for an easily accessible hinge. If the gearbox is easily accessible, you can apply grease to it manually.

A manual dispenser that needs to be restocked every month isn’t practical for places that are difficult to access, while an automatic one does it just once every six months. A continuous dispenser could be the ideal option for chains that need to be lubed frequently. Refer to an expert you plan to buy lubricants from for advice on the best way to go about it.

3. The Composition of the Lubricant

Even though the base oil in lubricants may seem simple, a wide variety of additives can be incorporated into the lubricant. The intended function of the lubricant informs the selection of these specific ingredients.

It applies to oils and greases alike. Simply put, greases are oils to which thickeners have been added.

But the choice of thickener is crucial. Generally, the thickener comprises fibrous particles that serve like sponges, trapping the oil and increasing its viscosity.

Each thickener has unique benefits and drawbacks, particularly in heat resistance, ease of pumping, shear stability, and water resistance.

4. The Lifespan of the Lubricant

Lubricants exhibit an ideal lifespan, but once that time’s up, you should replenish them with new ones.

If you don’t do it, you could end up with runout, metal-on-metal traction, ruined bearings, and other problems resulting in outages and increased expenses in the form of repair, maintenance, and replacement.

The primary concern is that you can’t always figure out when the service life is about to end.

Tracking the temperature at which your CNC machine operates is essential in keeping note of the remaining life of a lubricant. Excessive heat buildup degrades them as the lubricant’s service life will be lowered in half for every increase in temperature of 10 °C above 65 ℃.

The most accurate method for tracking heat is to employ digital calibration instruments with thermal imaging and vibrational analysis capabilities. It is also recommended that you keep track of the intervals between lubrication.

5. Cost Considerations

Most companies still only consider the upfront price of lubricants, even if there are other, more indirect costs associated with using an inefficient product. They frequently make purchases without thinking about how the product will affect the company in the long run, opting instead to focus on the price tag.

If you want to know how much lubricant costs, checking the price isn’t enough. The choice of lubricant also influences the total cost of equipment maintenance.

Proactive operators recognize that choosing the proper hydraulic fluid, as opposed to the cheaper or the best recognized, is a worthy task that will bring quality to their operations, despite the fluid’s relatively small cost compared to the machine itself.

After factoring in the price of lubrication and the cost of maintaining the equipment, the most significant expense is the money lost by the company due to unscheduled equipment downtime. Due to its propensity to place a heavy load on operations without any or little warning, it should also be considered when selecting a suitable lubricant.

Content Takeaways

Remember that not every lubricant is the same, even though they are necessary for the continuous functioning of all manufacturing facilities.

Simply purchasing an inexpensive lubricant without considering the abovementioned factors can be disastrous. In addition to being quite costly, breakdowns can quickly escalate in cost. Hence, smart companies put as much thought into lubrication as they do into the types of machinery they procure.

such a great tips.Thanks for share with us.I think it’s helps lot’s of people.Choosing the best engine oil for your vehicle involves more than just picking a popular brand. This requires understanding the specific needs of your vehicle and your driving conditions.I suggest you buy makkioil for your car to keep your car engine in good condition.

<a href=’https://makkioil.com/’>car engine oil</a>