I’m Jarrod Potteiger, education services manager for Des-Case, and today we’re going to talk about best practice oil sampling.

Oil sampling is, in a sense, the foundation of good oil analysis: it all starts with good sampling. If we don’t have good sampling, it doesn’t matter how good our testing is or how good our data management is because we can’t rely on that data.

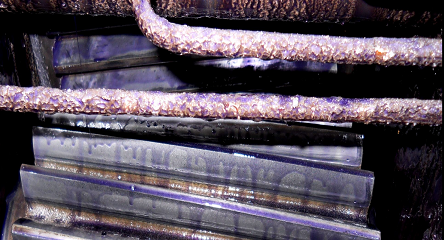

Our objective when we take a good oil sample is to get a sample of the oil that is lubricating the machine—the oil that’s actually between the gears, the oil that goes through the bearings or through the hydraulic pump. We want to see a sample of that oil and nothing else. We don’t want information about the tube that we’re pulling the sample through, or the machine that we just sampled, or the outside of the reservoir or the sump. We want to get a picture of the oil out of the machine, and we want to keep all other information out of that sample.

In order to accomplish this, we have to select several things correctly. We need to pick a good location in the machine, first of all. The location from which we take the sample is going to be different for different types of machines. For vat-lubricated sumps like gearboxes or pumps, we want to sample at least two inches off the bottom, two inches from the sides, and of course, two inches away from any moving components.

One other thing that we have to select here is how we actually get the sample from that location. There are different ways we could pull that sample out. We could open a drain port and let the oil flow out, but that’s usually very ineffective. It is inconsistent and gives us unreliable data. We could drop a tube into the sump and use a vampire pump but, in that case, we don’t have a lot of control over the point from which the sample comes. The right way to do this is to install a fixed sampling valve: a fixed hardware that allows us to pull the sample from the location we specify, in a consistent way every time.

If we have a circulating system, we want to sample in a location that’s going to give us good, consistent, and dense information. If we can, we want to sample from a primary return line coming out of that circulating system, and that’s going to give us information about all the lubricated components, and it’s going to be a consistent location.

If we’re talking about a hydraulic system, we may want to sample various locations, but there is more than one potential location. We could sample from the return line, we could sample after the pump and before the filter, or we could sample from the reservoir. Where we sample in that case really depends on what our objectives are.

Finally, once we’ve chosen the location and we’ve chosen the sample extraction method, we need to document that procedure and train all the technicians that take samples on that procedure because consistency in this task is extremely important.

So remember: sample location, sampling method, and high-quality sampling procedure. These are the keys to good oil sampling, and that’s the first step toward oil analysis.