Lubrication

Gold Mine Strikes Mother Lode, Decreases Lubricant Use by 7x!

Using a competitor’s asphaltic-based open gear lubricant to lubricate the ball mill’s open gear, the mine was concerned about the above average operating temperatures and excessive lubricant consumption – requiring one new quarter drum nearly every week.

- John Sander

- Lubrication Engineers

Extending the Life of Your Gear Oil

With consistent, accurate monitoring of the condition of your oil – whether in an engine, gearbox, circulating system or mainline power generation turbine – an oil analysis program can help you extend the life of the oil and protect the equipment.

- Nathan Walker

- Lubrication Engineers

5 Key Factors for Selecting a Suitable Lubricant

Earlier, general-purpose lubricants used to be enough to meet the lubricating needs of a given application. In the past, a person's experience and expertise were the primary factors in choosing a lubricant.

- Peter Jacobs

- CNC Masters

All About Industrial Grease

In this interview, John Sander, Vice President of Research and Development at Lubrication Engineers, goes in depth about industrial grease. He explains what grease is, how it is different from lubricating oil, how to choose the correct grease for an application, the different types of thickeners used in grease, the reason many grease formulators are moving away from lithium thickeners, the NLGI grease grade scale, and what’s coming in the future for grease formulators and end users..

- John Sander

- Lubrication Engineers

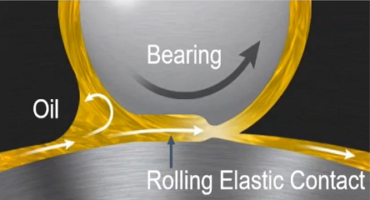

Intro to Tribology and Elastohydrodynamic Lubrication

Tribology is the science that studies the relationship between lubrication, friction, and wear. It is all about the lubricant film inside the bearing. The film that happens inside a roller element bearing, whatever the shape of the roller is, is referred to as Elastohydrodynamic Lubrication. Mina Soliman explains these terms more in depth.

- Mina Soliman

- Noria Corporation

Incidental Food Contact Lubricants

In this interview, John Sander, Vice President of Research and Development at Lubrication Engineers, dives into Food Lubricants. Food is an integral part of daily life, so it is very important. Most of us assume that the food we eat is clean and good quality. However, there are many places and times within the chain of food processing where it can be contaminated for numerous reasons. One of the ways to ensure safe and healthy food is for manufacturers to be aware of the lubricants they use in the process. Listen here to learn more.

- John Sander

- Lubrication Engineers

Solid Bar Lubrication for Kilns

Today, Clay Lockett, the Chief Executive Officer of Easy Bar Inc. will discuss how the company came up with this special lubricant called the Easy Bar.

- Clay Lockett

- Easy Bar Inc.

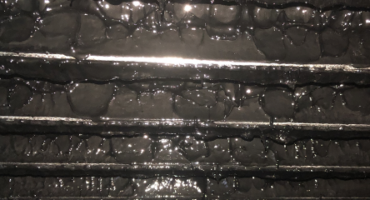

Kiln Lubricant Provides Exceptional Protection for Open Gears

Synthetic Oil Protects Slow-Moving, Straight-Cut Open Gears.

Pyroshield Syn Kiln Lubricant (9020) is a heavy-duty synthetic fluid designed to provide exceptional protection for high-load, heavy-shock, high-heat applications, particularly large shrouded and unshrouded open gears servicing kilns and ball mills in the mining, mineral processing and cement industries. It is recommended for slow-moving, straight-cut gear sets where flaking occurs using a conventional open gear lubricant.

- John Sander

- Lubrication Engineers

Filtration Prolongs Oil Life, Protects Equipment

Filtering new and used oil prolongs oil life and protects equipment from wear.

Studies have shown that as much as 70% of all premature machine failures can be attributed to contamination. To prevent these failures, it is important to purify the new oil as it comes into the facility and then keep it clean throughout its life. By establishing an ISO code cleanliness goal and maintaining it, you will extend the life of the oil and the equipment.

- Preston Rubottom

- Lubrication Engineers

- 1

- …

- 4

- 5

- 6

- 7

- 8

- …

- 15