Webinars

Introduction to Dynamic Testing

This introductory course provides a wealth of information about technologies that can help motor maintenance professionals maximize reliability of their electric motor plant machinery. The webinar will introduce attendees to static and dynamic motor testing. The complimentary nature of the two technologies is important to understand. This webinar lays a foundation to enable the maintenance professional to plan and execute maintenance strategies that minimize costly unplanned downtime..

- Drew Norman

- Megger Baker Instruments

Case Studies in Motor Testing

Join Noah as he discusses in depth various case studies involving Rotor, Servo, and Variable Frequency Drive motors. You won’t want to miss his expertise in discussing the motors, their characteristics, problems, and the testing used.

- Noah Bethel

- PdMA Corporation

Challenges of Monitoring Slow Speed Components on Critical Assets

In the field of vibration analysis, it is often argued that slow rotating components are the most challenging to monitor. When they are monitored, poor decisions and delayed detection are the result. However, just as with easily detectable high speed component faults, slow rotating components can have equal, if not better, success in early detection and prognosis. With adequate sampling techniques, and an easy to navigate software, you’ll increase your lead time detection and eliminate catastrophic failures. Presented by one of ONYX InSight's mechanical engineers, who monitors thousands of slow rotating and critical components in their portfolio - Jon Sharf will share his experience in this field.

- Jonathan Sharf

- ONYX InSight

Introduction to Electric Motor Testing and Monitoring Technologies

This introductory course provides a wealth of information about technologies that can help motor maintenance professionals maximize reliability of their electric motor plant machinery. The complimentary nature of the two technologies is important to understand. This webinar lays a foundation to enable the maintenance professional to plan and execute maintenance strategies that minimize costly unplanned downtime..

- Leslie Reed

- Megger Baker Instruments

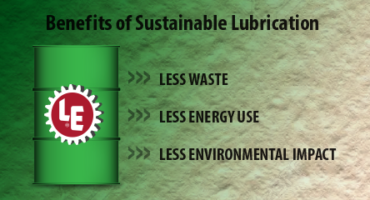

Lubricants Can’t Be Green … Can They?

Is it possible for lubricants to be considered environmentally friendly? Learn about how biodegradability, bioaccumulation and ecotoxicity tests are used to measure the environmental impact of lubricants. Beyond that, find out how lubrication programs can be green through responsibly planned purchasing, storage, use and disposal – a challenge to the limited regulatory view of green lubricants that fails to consider longer lubricant and component life, and decreased energy use..

- John Sander

- Lubrication Engineers

Condition-based Monitoring Signal Chains and Solutions

This webinar will review use cases and applications for Condition Based Monitoring (CBM) for industrial equipment. The presenters will review system design considerations and how the cloud can be leveraged for data analysis, reporting, and remote monitoring

- Perfecto Martinez

- Arrow

Profitable Condition Monitoring

This webinar covers how condition-based maintenance fits into Industry 4.0 and examples of what a KPI toolbox can include. Hedlund provides models, such as the DuPont model, that show how we can use CBM to influence the ROI of a company. At the end, he illustrates his point with a case study from a paper mill.

- Håkan Hedlund

- SPM Instrument AB

How to Diagnose the Root Cause of an Overheated Gearbox

This session will show you how to find commonly misdiagnosed or overlooked issues. A case-study example of a medium-sized gearbox with a seemingly obvious lubricant failure will be presented to illustrate how data can identify a lubricant selection problem. Attendees will learn how to apply this knowledge to future oil analysis reports so they can correctly diagnose the true root cause of an alarmed condition.

- Evan Zabawski

- TestOil

Understanding Vibration Analysis of Fluid Drives Systems

This webinar will be unveiling the benefits of fluid drive basics, internal configuration and the basic vibration analysis expertise required for detecting some common faults associated with the components. Live scenarios vibration data and case studies will be utilized in demonstrating the requisite knowledge required for diagnosing fluid coupling failures..

- Michael Osagada

- LafargHolcim

- 1

- …

- 23

- 24

- 25

- 26

- 27

- …

- 39