Articles

Arc Flash Studies: Why and When Are They Required?

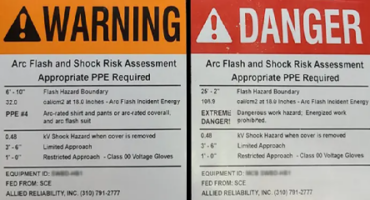

For employees to work on exposed live (energized) circuits, an arc flash hazard assessment is needed to determine the incident energy available at the equipment and what personal protective equipment (PPE) is needed to work safely...

- Michael Levitt

- Allied Reliability

Cost Avoidance Within the Infrared World

Who does cost avoidance? What is it? Where would you apply it? Why would you worry about it? These are the questions that one should ask themselves. Most of the time is spent doing the physical work and analyzing that data to determine the condition or health of the equipment rather than thinking what our group did to save the company money. This article explains the methodology we used and why you should care about cost avoidance.

- Patricia Warner

- Cummins Inc.

Check Sheets- Something is Missing, I Think…

Have you ever completed an infrared survey and wondered if you’ve missed something that should have been inspected? Do you know the special safety instructions to open certain electrical cabinets? Has management ever asked you when was the last time that you’ve inspected a specific cabinet and you couldn’t answer them? If you have answered yes to any of these questions, you need to develop a check sheet for the equipment that you inspect.

- Patricia Warner

- Cummins Inc.

Getting Started

Welcome to the home of condition monitoring; CBM CONNECT! The site is designed to provide you with educational articles, videos, and podcasts...

- Jason Tranter

- Mobius Institute

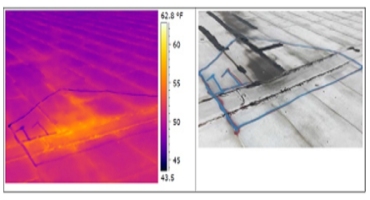

Thermal Tuning

Your images are very nice, like the ones shown below. After all, you tell yourself, if there was a serious problem I would have seen it...

- Luca Del Nero

- DarkWave Thermo

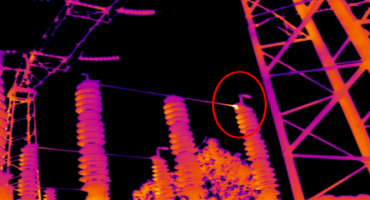

10 Things That Can Make You Misdiagnose With IR

An IR inspector cannot be an expert in everything but should at least be well informed about the potential problems that can be found during an inspection...

- Luca Del Nero

- DarkWave Thermo

EMSDs: Streamlined Maintenance and Reduced Downtime

Electrical equipment requires periodic maintenance to continue to operate as designed, and it is well understood that this maintenance saves money in the long run...

- Martin Robinson

- IRISS Inc.

The Key to Machinery Reliability

The goal of Minnkota’s PPM (planned preventative maintenance) Team is to use their technologies and resources to provide the workers with safe, reliable operating equipment and make a positive impact on their maintenance...

- Tod Baer

- Minnkota Power Cooperative Inc.

CMMS – Friend or Foe?

In every good maintenance program, there needs to be a place to store a history of problems found and actions taken if we are to learn from our experiences and continuously improve...

- Paul Dufresne

- Reliability Playbook, in Partnership with Lubrication Engineers

- 1

- 2