About the Author

During my many years as a vibration analyst and reliability expert & have witnessed belt driven machines that are “Bad Actors” which are unreliable and have chronic failures. Misalignment issues like this case are why the B.A.T. Belt Alignment Tool® was invented.

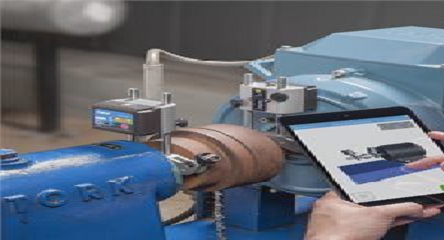

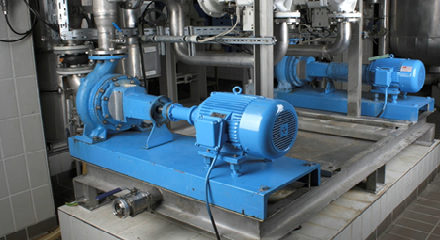

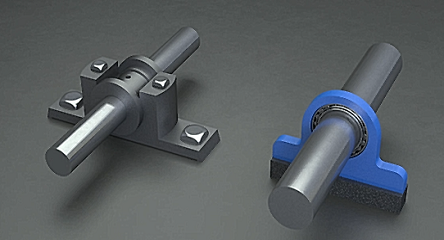

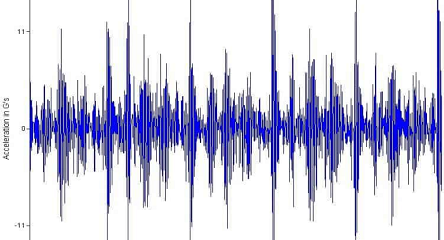

This blower has a base mounted the motor on the fan pedestal and it was a chronic “Bad Actor” which frequently tore up belts & showed high vibration readings indicating that there were belt problems. When the alignment was checked with a single laser belt alignment tool it did not show a misalignment condition. However, the blower still mysteriously destroyed belts & other system components. Over 8 years it destroyed 28 sets of Belts (84 Belts), 3 Sets of Bearings & 2 Drive Shafts. When the alignment was finally checked with a B.A.T. Belt Alignment Tool® it showed the “TRUE” severe misalignment. It was so far out of alignment that it required .200” shims on the outboard motor feet for the correction. After shims were installed, Vibration was reduced to acceptable levels, efficiency and reliability were restored. The B.A.T. Belt Alignment Tool® showed the true misalignment and made the correction moves obvious, fast and easy the first time.

Hi Mike Olszewski,

Thanks for your information.

Could you also share what kind of freq. will be occurred when soft foot?

Thank you so much.