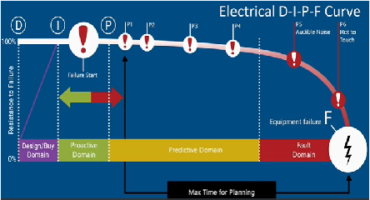

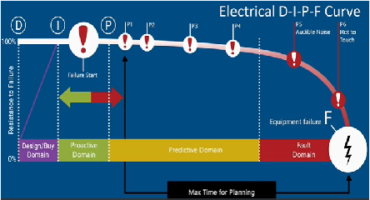

The D-I-P-F curve goes from design and implementation to potential and functional failure. When your plant is ordering new electrical assets, it’s a good idea to find out if you can get the switchgear designed to be ready for infrared and ultrasound analysis. Is there an OEM out there that can do that? These are things to think about to save money in the long run and to improve safety in your plant.

A major part of asset and procurement relies heavily on the input from the original equipment manufacturer (OEM). We must be telling the OEMs that infrared and ultrasound are essential. It should be a standard fit, not an extra. As much as 60% of failures and safety issues can be prevented by making changes in design. 80% or more of a facility’s life cycle cost is fixed during the plan, design, and build phases. And 30–40% of equipment breakdowns are related to poor equipment design or condition.

For example, the Tornado aircraft came out in 1975 or 1976, before night vision systems were operated. After the Gulf War, it was decided that the Tornado needed to fly at night, so they decided to take one of the guns out and put a night vision camera in. But the pilots needed to wear night vision systems on top of their helmets. In peace time, you’re not allowed to take off and land with the night vision systems on; pilots had to put them on in the air. So the pilots would have their helmets on with the night vision goggles in the air, and then they’d lower the cockpit, and the cockpit would hit the top of the night vision because the plane was not designed for that. So they ended up lowering the seats. But it needed a completely new redesign.

After the design domain comes the proactive domain, and this is where we start seeing failures. During the proactive and predictive domains, we use ultrasound, infrared, visual inspections, and other CBM techniques to make sure we don’t reach the fault domain. If we leave the equipment to fail, it will cost a fortune in loss of productivity, and also to replace the switchgear. If you can maintain it in the predictive domain, the equipment will keep going a lot longer. You can save up to 10–15% of the life of that equipment.

Critical Asset Surveillance Technology (CAST) products assist in ultrasound, partial discharge, infrared, motor circuit analysis, voltage and current measurement, and visual inspections. CAST detects problems in the early stages: Stage 1 with corona, Stage 2 with tracking, and early Stage 3 with the heightened temperatures. After Stage 3, the equipment becomes hot to the touch and there is audible noise before it finally fails.

Early Signal 1 CAST Inspections include ultrasound, partial discharge, infrared, MCA, voltage and current measurement, and visual inspection. These are the first line of defense. We don’t have

to use our fully qualified engineers for this—as long as the inspectors are properly trained in the technology, they can be apprentices; all they are doing is collecting data here.

Inspection results in Stage 1 include corona, which makes a distinctive sound that you can hear with ultrasound equipment. This is one of the first signs of failure in electrical equipment. MCA testing may show a slight increase in resistance. No abnormal thermal patterns will be detected at this stage. Electrical maintenance safety devices (EMSDs) can be used to perform infrared and ultrasound.

Inspection results in Stage 2 include tracking, which also makes a distinctive sound through the ultrasound equipment. MCA and resistance and voltage testing will also pick it up. Thermal patterns start to develop, and you can view those via the EMSDs (inspection windows).

Early Stage 3 inspection results include arcing, which you can also hear with ultrasound. If you can hear arcing, things are getting dangerous. After arcing comes complete meltdown. Arcing will also be picked up by MCA and infrared.

After this, all CBM inspections will continue to degrade until failure if nothing is done. But if you do enough maintenance at Stage 1, you will not get to Stage 3.

The value of CBM is dollars. Your plant will save a fortune.