Five Minute Facts

Triaxial v Single Axis – More for Less

Over the years, advancement in microchip technology and minimization of condition monitoring devices has led us to the next generation of condition monitoring triaxial sensors.

Customer X has been running a condition-based maintenance (CBM) program since the turn of the century, utilizing a hand help data collector and single-axis accelerometer, it was taking around 7 days to monitor their critical asset population of around 250 units.

With today’s ever-demanding focus on efficiencies and cost savings, they looked towards AVT Reliability® for support and guidance on helping them rationalize their CBM program and reduce data collection time and operational costs.

AVT Reliability® proposed a move from their current system, to the Machine Sentry® model, of web-based portal, windows mobile or android handheld devices, and our blue tooth Triaxial Sensor.

This strategic change to the Machine Sentry® system allowed for a greater number of vibration measurements to be taken, the inclusion of additional parameters, such as visual inspection and temperature measurements, all of which can be monitored in around 2 days.

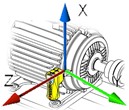

So what is Machine Sentry® Triaxial Sensor? It is a sensor that can measure up to 3 simultaneous planes X, Y & Z at the same time, it also includes an inbuilt temperature sensor for spot temperature recording and an external port for connection to fixed sensors and displacement probes.

When paired to the Machine Sentry® Handheld device, and the Machine Sentry® web-hosted software, the end-user has more flexibility than ever before.

Routine based condition monitoring is a ‘comparative’ route-based monitoring program where trending of vibration measurements is the primary requirement, supported by vibration spectra for fault determination, as long as the triaxial sensor is placed in the correct location, and in the correct orientation, repeatable and representative measurements will always be achieved, and faster.

The benefits of triaxial sensors include:

-

- Speed of data capture is up to 5 times faster than single axis.

- Triaxial can capture data from one measurement location but in all three planes.

- Significant cost and labour saving.

- Easier on the operative, reduced bending movements.

- Change orientation by selecting its corresponding image.

- More complete set of data for the analyst.

AVT Reliability® has been operating equipment condition monitoring programs for over 40 years utilizing what was considered conventional technologies, Machine Sentry® Triaxial Sensor has allowed us to unlock a vital resource and utilize it in other parts of the business.

Customer X reduced his program spend from circa £72000.00 per year to £18,000.00 per year.

A clear example of more for less!