Two Minute Tips

The Proven Usefulness of Data In Industry

Data, and the insights mined from this data, are extremely valuable for industry. With proof of concept and results, all projects show drastic increases in yield, uptime, efficiency, etc. However, each of these projects require a single, common starting point: available, qualitative data!

The following examples prove that collecting the correct data, in addition to using all of the predictive techniques available, can prevent serious errors that would have cost you a great deal of time and money.

-

Vibration measurement

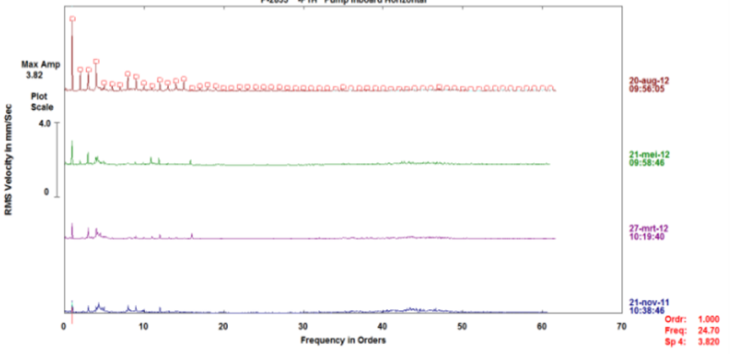

If synchronous energy (1x speed and multiples) is detected during the vibration measurements (see plot below), various causes are possible:

- Shaft/bearing clearance or looseness

- Coupling/alignment problems

- Structural problems

- Other low-frequency problems

At that point, it may be useful to apply other techniques to track down the exact damage pattern.

- Are the vibrations mainly located at the coupling or not?

- The use of a stroboscope can provide information about the condition of the coupling.

- See the first and second video at the bottom of the text.

-

Belt wear/belt slip

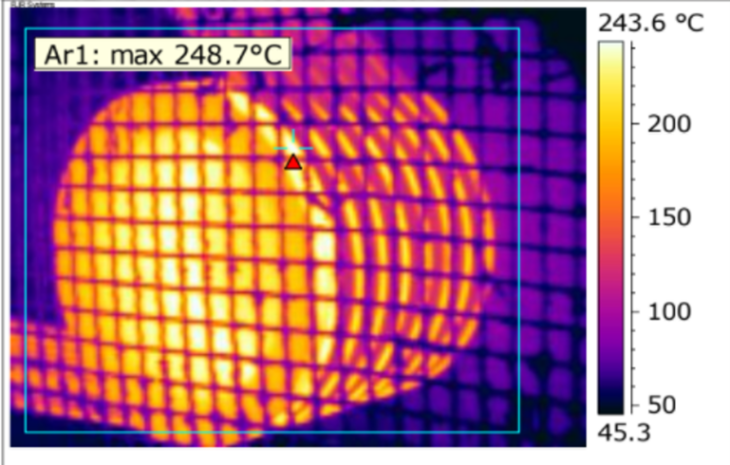

If vibration measurements show that the normal speed can no longer be reached, this may indicate belt wear, in particular belt slip. At that point, additional information can be provided with the aid of other techniques, infrared measurements in this case. The example below shows that the temperature has risen to 248 °C due to the slipping of the belts, which is unacceptably high. This measurement indicated the seriousness of the situation very quickly, after which the installation was shut down to replace the belts. FYI: Due to the slipping of these belts, the pump only reached a speed of 99RPM instead of 313RPM, which meant it was well outside of its operating range, and could not deliver sufficient flow.

-

Motion magnification for structural problems

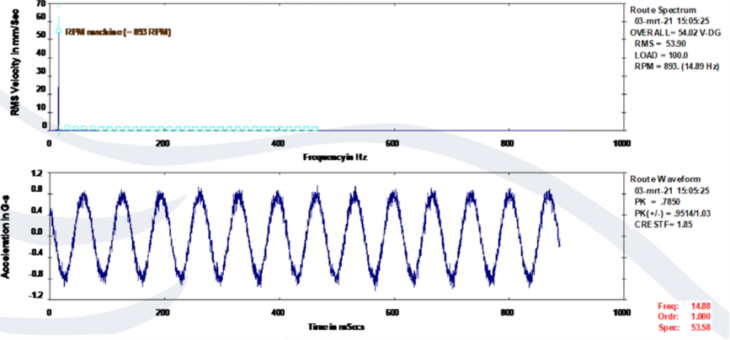

When a very high 1x speed component is detected during vibration measurements, various causes can be found.

To rule out the possibility of a structural problem in the setup, it is possible to have measurements carried out with a motion magnification camera. The aim of this camera is to visualize low-frequency energy which cannot be seen with the naked eye.

Therefore, 2 techniques are combined in order to provide the most appropriate advice. In this example, a very high 1xRPM component is present in the vibration spectrum (see plot below). In this example, a very high 1xRPM component is present in the vibration spectrum (see plot below).

If we look at the images from the motion magnification camera, we see the following: the entire structure moves in an axial direction/twist. This indicates that the structure is not rigid enough to withstand the forces arising from Drum M1. Besides that, some anchor points are not sufficiently attached to the ground.

- See the third and fourth video below

This gives you a good idea of how the set-up moves and where it needs to be strengthened.