Let’s discuss for a moment; how can we design a decent, standalone sensor which can be put on the vibrating equipment, stay there and report reliably the measurements.

Let’s look at very frequent set of requirements:

- It is going to withstand (and measure) potentially very high g forces in excess of 50g

- It is going to withstand (and report) temperature over 60°C (140°F)

- The place is hardly accessible (not good for frequent human inspection)

Additionally, we would like the sensor to measure very precisely the equipment RPM (may be very slow rotating equipment) but at the same time detect very high frequency events

around 10kHz (hitting the ‘hard-spots’)

This is all becoming possible nowadays in the battery powered equipment but there are some limitations in the way. We can understand that there is practical limit for handling the sensor which does not have to be neither very big nor too small. There is obvious realisation that a lightweight sensor is easy to attach, and it is more likely that a smaller object can fit easier within the space provided.

Another point is not so obvious:

The smaller is the sensor and any of its electrical components, the more likely it can withstand very high g forces.

The tiny battery of small sensor dictates focus on low power and efficient RF link.

The lower is the frequency of operation, the greater is the RF link over the distance. Sub GHz ISM (Industrial, Scientific and Medical) bands are available to use for such applications E.g. 868MHz, 433MHz, 315MHz.

These frequencies have wavelengths of 34.5cm, 70cm & 95cm and are close to the frequency range already used for some of the M2M communications and Smart Metering (‘450 MHz band’).

Availability of any lower frequency would be nice but not offering advantage for the tiny sensors, as there is practical limit of the electrically shortened antenna efficiency.

As for vibration sensors, any use of the modem in licensed ‘450 MHz band’ is currently prohibitive, not just because of the equipment cost but in large part due to higher energy usage in data exchange. It is obvious that reporting of the vibration sensor every several minutes is much more frequent than Smart Meter (every several hours) and vibration sensor needs to remain very energy efficient. More importantly, the modems require high current pulses, which in case of small sensor battery must be buffered with massive capacitors, and these are not designed for high g forces experienced by the vibration sensors.

These details are subject to change and most likely in the future we would be able to use tailored 5G/6G solutions more suitable for the sensor needs. As for now, with current mobile networks deployments, there is much focus on bandwidth and GHz frequency bands suitable for the mobile entertainment. Human centred wireless does look for the highest possible data capacity and lowest bi-directional link latency in human-to-human or human-to-equipment interactions.

Ideally vibration sensors are required to report the readings reliably but with the lowest energy per data used.

This indicates the main reason for the bespoke solutions like using the unlicensed ISM bands.

In ‘450MHz band’, the achievable distance is doubling that of 900MHz (frequency reduced by factor of two offers significant 6dB advantage). This allows maintaining a more reliable connection or reducing number of gateways by factor of 2 – 4 when aiming to achieve similar area coverage.

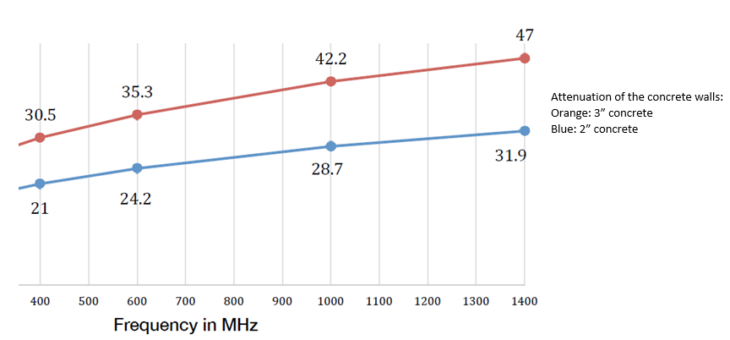

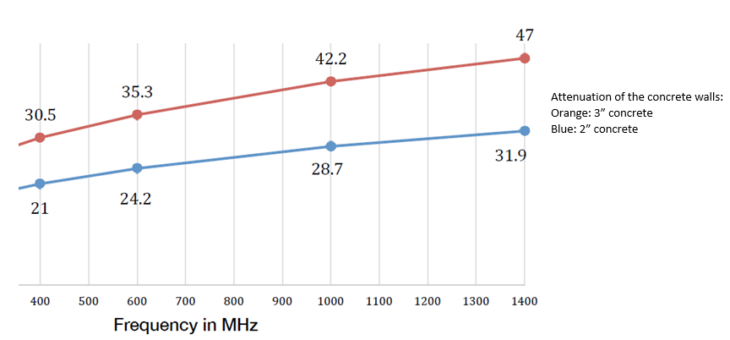

The advantage of lower frequency band is also clearly visible when comparing very strong attenuation of higher frequency signals passing through thick structures like the concrete walls.

Graph showing the Decibel attenuation level across Frequency (from Phillips Laboratories “Measurement of RF Propagation into Concrete Structures…”)

On the small sensor’s side, one thing is the most likely to remain the same in the future: staying with low frequency bands for the sensor’s communications, in order to save the battery life and being able to maximise link budget with low transmit power of the sensor (or to minimise number of dedicated gateways to receive the sensors data in the area covered), whilst offering a robust communications link in an industrial environment.