Spectral bands can be a very useful tool for the detection of machine faults. However, not all condition monitoring analysts use them or take advantage of their full potential.

The definition of parameters that monitor the value of narrow spectral bands in the spectrum can be particularly helpful when using online condition monitoring systems, as a way for the automatic detection of faults or anomalies on the machine.

When vibration data is taken using a portable system, analysts can get a pretty good idea of the general status of the machine while they perform the measurements, signaling those machines that are in good condition, and those where an anomaly may be present and require further analysis.

For online condition monitoring, however, no analyst supervises typically all the signatures and parameters the system measures and stores. The amount of data to be analyzed when taking measurements with a portable analyzer is quite limited, while with online systems the amount of data measured and stored can be quite big, making it infeasible or impractical for an analyst to look in depth at all that much data.

Therefore, an automatic detection of anomalies on the data is most needed and strongly recommended in case of online condition monitoring systems. For this purpose, the use of narrow spectral bands is a great help as a first approach for solving this problem, along with the automatic or semi-automatic configuration of alarm levels.

Experience shows that using only overall vibration values (velocity and acceleration) falls short in many cases. Using narrow spectral bands, on the other hand, along with other types of vibration parameters (peak-peak values, crest factor, kurtosis, etc.) is an inexpensive and straightforward technique that can greatly improve the capability of detecting anomalies with respect to solely monitoring overall values.

In the example below, three graphs corresponding to a machine with a belt problem are presented:

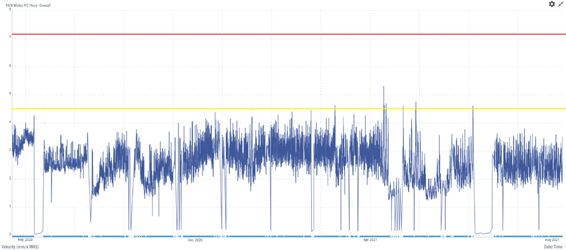

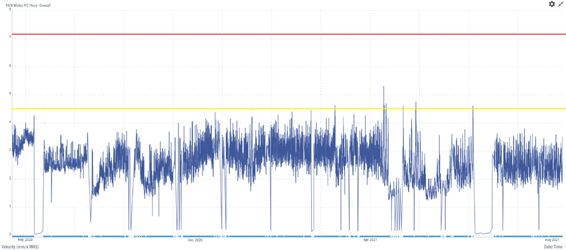

Overall vibration value on motor – velocity

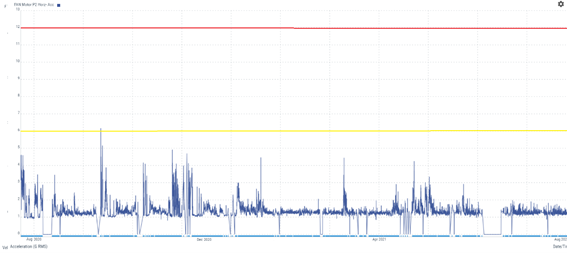

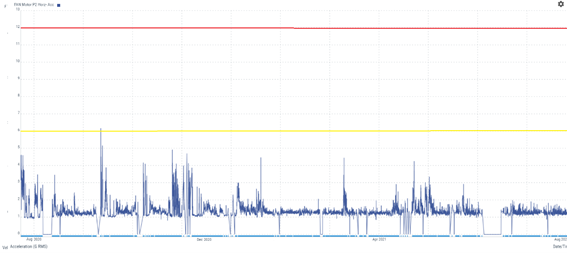

Overall vibration value on motor – acceleration

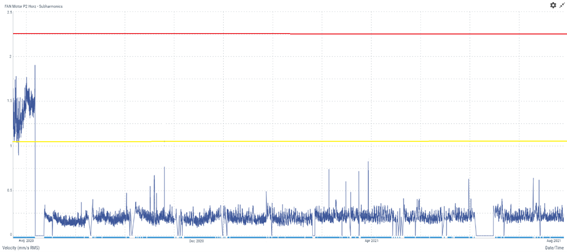

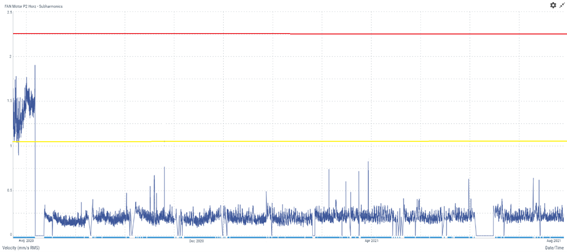

Subharmonic spectral band vibration on motor

Overall vibration values, both velocity (up to 1 kHz) and acceleration (up to 20 kHz) showed no significant increase on its amplitudes along the time. However, the “subharmonics” narrow band did show clearly amplitudes higher than normal, above the statistically-configured alert level. Following an overhaul of the machine in August 2020, in which the belt problem was corrected, a significant decrease in this amplitude can be observed.

The spectra taken before the maintenance intervention showed an abnormal peak amplitude at the belt pass frequency that completely disappeared after its correction. This fault would have been unnoticed if the online monitoring system had been based only on the overall values and had not also specifically monitored these spectral bands.

The use of narrow spectral bands have demonstrated over the years to be an effective and inexpensive tool as a first approach for the automatic detection of anomalies on vibration data, and a great help when using online condition monitoring systems along with an appropriate method for setting up its alarm levels.

How could you set the alarm and alert level for each band ?