Compressed Air Survey leak & Energy Saving Case Study

– Introduction:

-Compressed Instrument air System is a vital system for the operation of steam and gas turbine control systems like (pneumatic equipment, valves & electrical controls.

….) Therefore, it is important to make it work efficiently and effectively without any problems that might affect its operation & Performance.

- Compressed air is a unique utility for most plants since it is one of the few where the plant has complete control over the production, distribution, and use of the utility.

- 80% of the electrical energy used by a compressor is converted to heat.

- In many facilities& Industrial’s leak detection instruments are used for safety, environmental, energy or quality assurance programs:

- Compressed air costs money! Avoid energy loss by fixing your leaks

- o Industry average 31% of energy use can be avoided by just fixing leaks!

- o Reduce running hours / wear and tear on existing equipment

- o In many cases a lower spec or shut down of a compressor can be the result

- Production efficiency

- o Achieve better efficiency of the process

o Run pressures or vacuum pressures at desired levels

Fig 1 – Ultra probe 15000

-Case Description

- During Daily Operator Walk through around plant, he observed the two Instrument Air Compressors A & B doing loading and unloading continuously during the normal operating mode of the Steam turbine area, this is considered abnormal because the compressor should be do loading and unloading for a few minutes (more than 300 second) of time and shutdown when there is no air consumption on the network like steam outage shutdown.

- The Pressure of Air in system approximately 7 bar

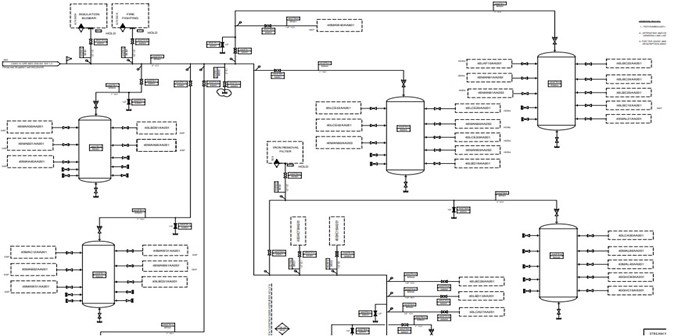

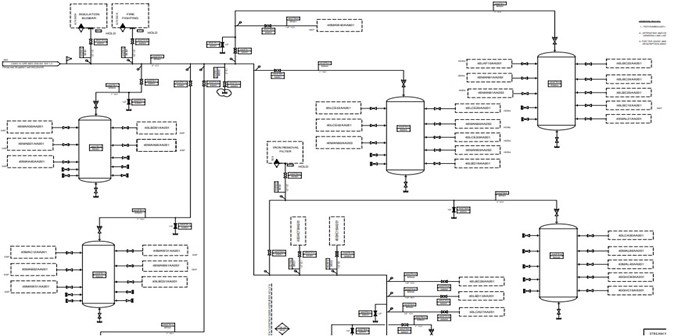

- During Period of the first shutdown of unit, CM Team put plan to do Air leak survey for all air network points, by using Ultrasound device UE 15000 and using PID Of system to check all sources of air Supply.

Fig 2 PID Of Control Air System -Steam Turbine

Tools Used through Survey

- Ultraprobe 15,000.

- DHC Noise Isolating Headphones.

- LRM Long Range Module.

- RAS/RAM Remote Access Sensor.

Fig 3 UE 15000 Device with Accessories

-Walk through and air leak mapping as PID DRW in all Connection and Supply

Airline to all Control valves, Air collection Reservoir, Electrical air sealing and firefighting system …etc.) By Air borne Ultrasound device (UE15000)

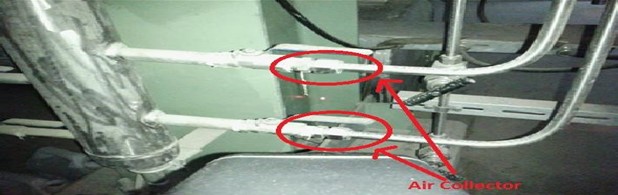

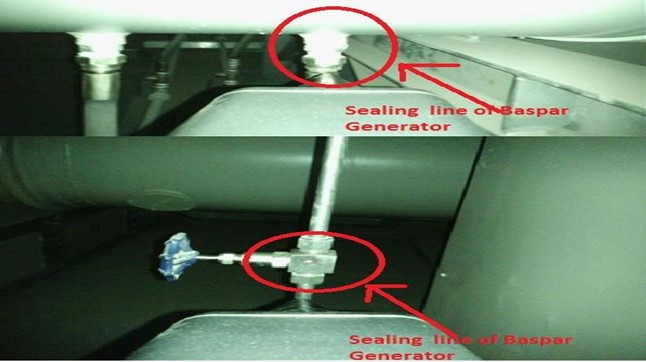

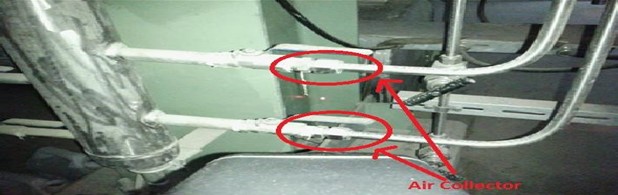

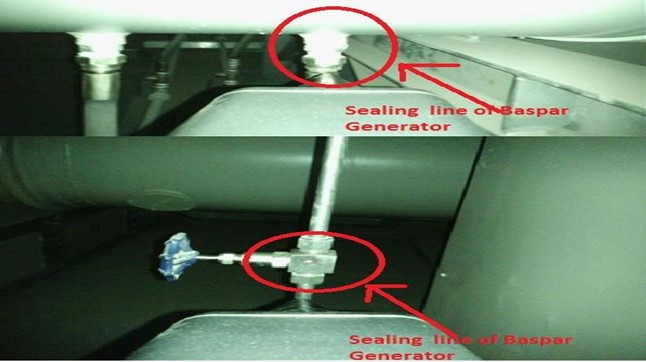

– Below are examples of some of the leak points that have been discovered:

Fig 4 leak from Safety Air Storage

Fig 5 leak from Air Collector

Fig 6 leak from Regulator of feed water Pump

Fig 7 leak from Sealing line of Baspar Gen

Fig 8 leak from Sealing line of Basbar Gen

Fig 9 leak from IP steam shut of valve

Comp Air Leak Suervy Saving Energy Case Study_ 6

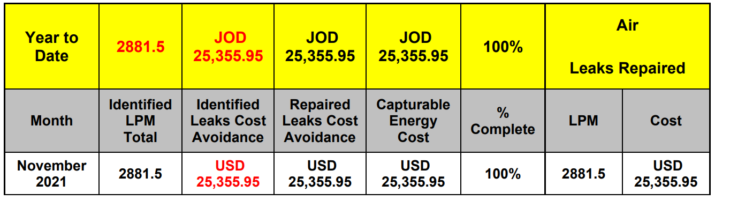

Table1 UE Ultrasound Survey Results

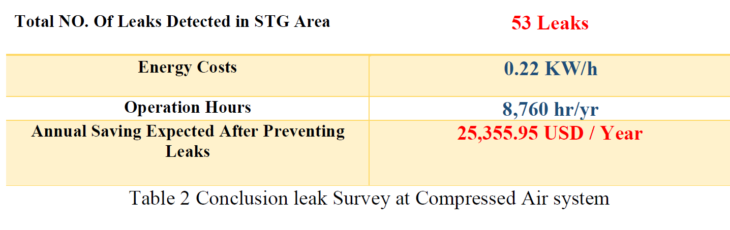

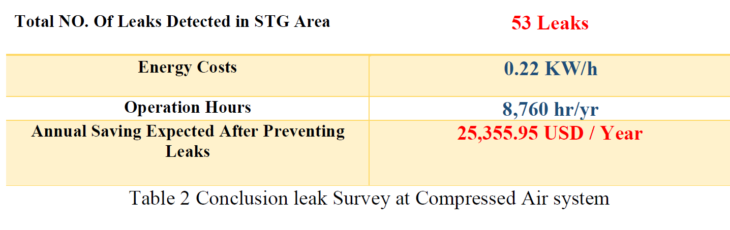

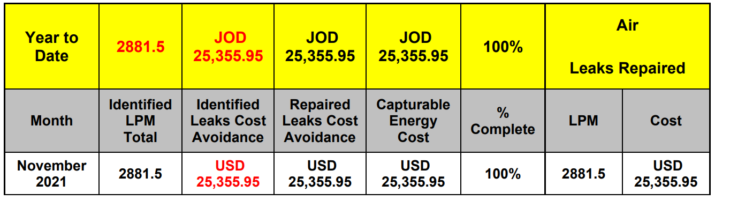

– Below Table illustrated the conclusion leak Survey Finding in Compressed Air network:

– AIR LEAK ASSESSMENT SUMMARY

- Total No. of leak in Compressed Air system: 53 leaks

- Annual Saving Expected After Preventing Leaks: 25,355.95 USD / Year

Conclusion &Benefits:

Conclusion &Benefits:

-Compressed air is one of the most costly utilities in a facility today, A simple program of leak inspection and repair can go a long way towards reducing excessive energy costs.

-Saving Energy Cost losses yearly by (25,355.95 USD / Year).

- Increased Reliably of Air compressor and extended lifetime.

- Safety & health accident will avoided by fixed Pressurized pipe leak to working area.

Conclusion &Benefits:

Conclusion &Benefits: