About the Author

Howard Penrose

President, MotorDoc LLC

Howard is the President of MotorDoc® LLC and the 2018 Chair of SMRP. He has over 35 years of electric motor testing, repair and design experience, starting with a US Navy motor repair job to advanced electric machinery design. Howard is also involved in legislation with the US Government regarding Cyber Security, Infrastructure, Energy, SmartGrid Education and Safety.

READ FULL BIO

Great presentation Dr. Penrose

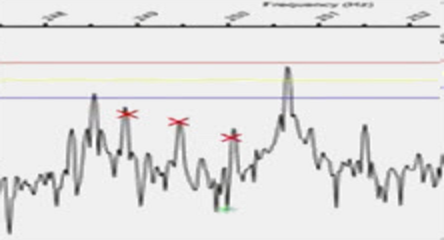

In the evaluation slide, you mentioned that the time between inspections for bearing fault detection is about 1.5 months using ESA (versus 3 months using vibration). Is this P-F duration related to the difficulty of detecting incipient bearing faults using motor current ?

Mohamed

The detection to failure was specific for this application – which is based on a real application where we had this experience. There are other times where vibration will detect bearing problems well in advance of ESA. In other cases, it is safer and faster to use ESA such as with wind generators even if the bearing faults will be detected later in failure stages.

Howard