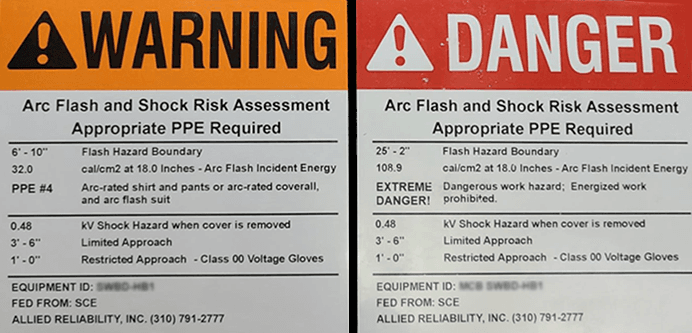

For employees to work on exposed live (energized) circuits, an arc flash hazard assessment is needed to determine the incident energy available at the equipment and what personal protective equipment (PPE) is needed to work safely.

The analytical techniques used to conduct an arc flash hazard analysis are described in IEEE Guide for Performing Arc-Flash Hazard Calculations, IEEE 1584, and the Standard for Electrical Safety in the Workplace, NFPA7OE. There are minimal differences between the model calculations.

The arc flash analysis of the electrical system in the facility will provide the following outputs:

Once the arc flash hazard analysis has been conducted, all equipment is labeled, and personnel are trained to work safely around energized circuits. Additionally, the Standard for Electrical Safety in the Workplace, NFPA 7OE states in Article 130.5 that an arc flash study needs to be reviewed every five years or whenever there is a significant change in the electrical system. The five-year interval is a straight-forward requirement.Determining a significant change can be left up to interpretation. Whenever there are changes to the electrical system, the single-line diagram must be updated, and the arc flash hazard analysis needs to be reviewed. While adding small motors or new equipment may not affect the arc flash boundaries or incident energy of existing equipment, you will need this information to label the new equipment.

The review of the arc flash hazard analysis should be conducted formally. This requires documentation. Documentation can include reports of the analysis, meeting notes, and process reviews associated with any change management system used by your organization. I recommend keeping all quality documentation related to the arc flash hazard review on file for at least three cycles – the current arc flash hazard analysis plus the past two arc flash hazard analyses.

References:

1. National Fire Protection Association (NFPA). Standard for Electrical Safety in the Workplace, NFPA 70E-2018. Quincy, MA USA

In his current role, Michael Levitt is the general manager of Allied Reliability’s electricals division and is certified in all the competencies they represent.

Michael has more than 30 years’ experience in designing equipment, systems, and performing testing on power distribution systems, power distribution equipment, and associated components.