Five Minute Facts

What is MCA?

MCA™ is a field proven very easy to use and safe method of evaluating the condition of electrical equipment while the equipment is deenergized. The basic premise of MCA:

In equipment with three phase coils all phases should be identical. Consequently, all the electrical characteristics of the winding should be the same. If any change in the condition of insulation occurs, it is never good, (windings do not “fix” themselves). So, any change in the winding insulation system is “bad”. The phase coils have 2 separate and independent insulation systems The groundwall insulation system and the winding insulation system; the condition of one insulation systems doesn’t indicate the condition of the other, therefore each insulation systems needs to be tested thoroughly and independently. The groundwall insulation system isolates the coils from the equipment’s frame or other exposed parts of the equipment while the winding insulation system directs the current through the conductors to create the magnetic field. MCA™ performs a series of tests on both insulation systems.

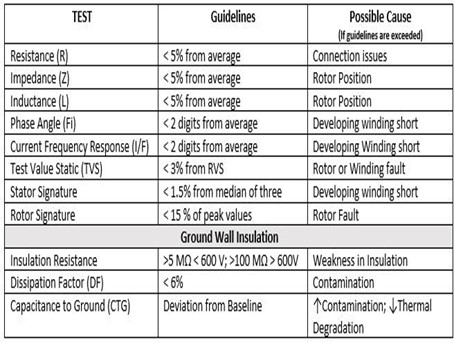

Groundwall Insulation: Breakdown of the groundwall insulation system is a safety issue and requires immediate action. MCA™ measures the insulation resistance to ground measurement to locate any weaknesses in the groundwall insulation but doesn’t provide the overall condition of the insulation. Dissipation Factor (DF) and Capacitance to Ground (CTG) reading provide additional indication of the overall condition of the ground wall insulation system, but none of these provide any indication of the winding insulation system.

Winding Insulation: A breakdown in the winding insulation system will result in shorts between tuns in the windings which results in weakened magnetic field, unbalanced current flow, increased heating, and eventual atastrophic equipment failure. MCA™ performs a series test by applying low voltage AC & DC voltage to the three phase windings while the motor is deenergized. The DC voltage measure the winding resistance using especially designed Kelvin leads to provide very accurate winding resistance measurements to identify connection issues.

When the winding insulation begins to degrade, it undergoes a change in the chemical makeup of the insulating material surrounding conductors. The AC current flowing through the windings exercises the entire winding insulation. The very small changes that occur because of the chemical makeup are measured and evaluated. By analyzing the amount and relationships the causes and severity of developing winding failures can be identified and the proper action recommended.

MCA™ can be used for:

- Incoming inspections on all new & repaired motors

- Spares testing

- Pre installation testing

- Troubleshooting

- Routine predictive maintenance testing

MCA™ Tests

Static Test – tests all three AC motors windings, performs a series of tests at different frequencies on all three phases of the motor’s windings from the motors line leads, T1, T2, T3. The results of the test are input into a proprietary algorithm to create the Test Value Static (TVS). The TVS is a dimensionless number that serves as a baseline value to defines the condition of the equipment. Any changes in this value > 3% indicates a fault. This value may be compared to other identical equipment (must be the same HP/KW rating, speed, frame size, and manufacturer).

What is MCA™?

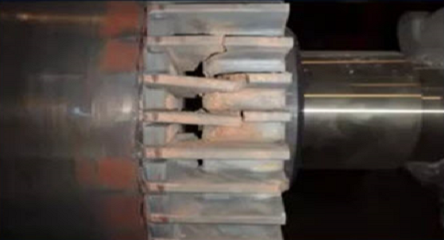

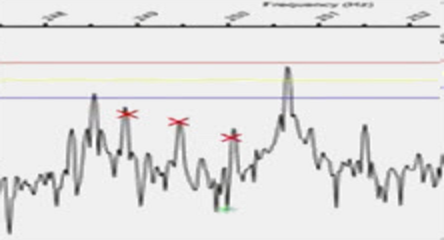

Dynamic Test – is performed on squirrel cage induction motors < 1000 V. While the motor shaft is smoothly and slowly manually rotated, stator and rotor signatures are created. The stator and rotor signatures are automatically analyzed to identify and report faults in either the rotor or stator.

Phase Comparison Test – tests three phase coils in all types of three phase equipment, including motors, generators, and transformers. The phase comparison or “Z” test measures, DC winding resistance (R), impedance (Z), inductance (L), phase angle (Fi) and current frequency response (I/F). The results of the tests are recorded and provided to determine any differences in the phases. These differences are compared to pre-determined guidelines created through many years of field testing the condition of the winding insulation. These values can be trended over time, used to determine the type and severity of developing fault, and provide an estimate of time to failure.

The following guidelines have been developed from over 35 years of field testing, but they are simply guidelines and are a good starting point, however, as with any guideline’s failure will not occur immediately if these guidelines are exceeded.

The basic procedures for MCA™ testing static and dynamic tests are performed all on new equipment to evaluate the new motors condition and establish base line or reference values for future testing. New baselines are established from the motor control center (MCC) once a motor has been installed. All future readings can be taken are if all measurements from the MCC are balanced all connections in the motor circuit are tight and the winding insulation surrounding the conductors in all the phases are in good condition. If an unbalance occurs, analysis and perhaps further testing may be same required to evaluate the type and severity of the fault. The AC tests measure impedance (Z), inductance (L), phase angle (Fi) and the current frequency response (I/F) to evaluate the condition of the winding insulation.

The basic procedures for MCA™ testing static and dynamic tests are performed all on new equipment to evaluate the new motors condition and establish base line or reference values for future testing. New baselines are established from the motor control center (MCC) once a motor has been installed. All future readings can be taken are if all measurements from the MCC are balanced all connections in the motor circuit are tight and the winding insulation surrounding the conductors in all the phases are in good condition. If an unbalance occurs, analysis and perhaps further testing may be same required to evaluate the type and severity of the fault. The AC tests measure impedance (Z), inductance (L), phase angle (Fi) and the current frequency response (I/F) to evaluate the condition of the winding insulation.