Transmission Measurements and Selective Radiance

Infrared (IR) thermography has never been a simple thing. Emissivity, reflections, and transmission rates for IR windows can cause confusion and frustration without the proper knowledge, experience, training, and skill. And those four qualities are exactly what ASNT (the American Society for Non-Destructive Testing) defines as certification. This paper will try and simplify the very complex subject of IR window transmission. One simple question before we get started: Why don’t IR window manufacturers list the exact transmission rate for their windows?

In order to understand this subject completely, I would highly recommend that a person attend an IR level II training class. Some of the definitions that need to be brought into this discussion are

Transmissivity:

The ability and efficiency of radiation to pass through an object/material. Examples: Visible light through glass, long wave IR (LWIR) through some polymers.

Blackbody:

A perfect emitter and absorber of radiation. Emission and absorption will be at 100%, while reflection and transmission are at 0%. Perfect examples do not exist.

Graybody:

A material with an emission less than 100%, but remaining constant throughout the spectral waveband. Example: An object that has an emission of 90% for a long wave IR camera would also have a 90% emission for all other bands of IR along with other types of radiation. Perfect examples do not exist.

Realbody/Selective Radiator:

A material with an emission less than 100%, and which changes throughout the spectral waveband. All materials exhibit this type of emission.

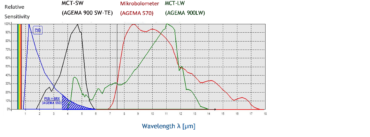

All thermographers, with or without structured training, have heard of emissivity and how it will impact temperature accuracy when using IR cameras. The incorrect value can lead to large temperature errors. But we also must be aware that the emissivity of a material may not be the same from one type of IR camera to another. Below is an example of a real material and how emissivity can be different for different cameras.

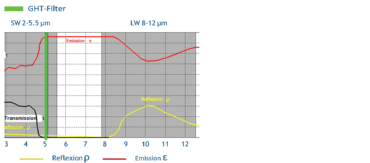

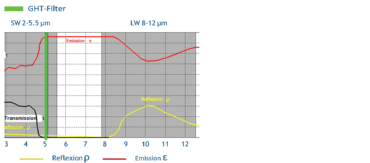

The red curve above is the emissivity curve for glass from 3 to 12 micrometers. The two gray bands show the areas where modern temperature-measuring IR cameras are. Note that the emission rates fluctuate considerably. We should also note that IR cameras will have a system response curve across their selected waveband (3–5 or 8–12 um), and will NOT sense the various wavelengths equally well. That being said, if one LWIR (8–12 um) camera senses 10 microns at its peak and another LWIR camera senses 9 microns at its peak, those two LWIR cameras will NOT measure glass with the same emission. One camera might need a .88 emissivity while another needs a .78. How do you know? The best and only way to know the emissivity of a material is to measure that material with YOUR camera. Not all LWIR cameras will achieve that same result on some materials. And most MWIR (3–5um) cameras will give a different result over the LWIR cameras.

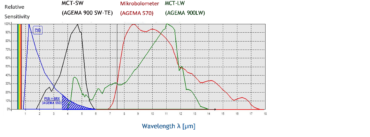

Here is an example of a system response curve for a particular IR camera (note the completely different responses for the Agema 570 and 900 LWIR Cameras):

If the emissivity of a material varies with wavelength, it must have a varied transmission curve. The major reason why IR window manufacturers cannot give exact transmission rates for a waveband is because IR cameras will have various system responses and may not give the same result. This includes different LWIR cameras from the SAME manufacturer.

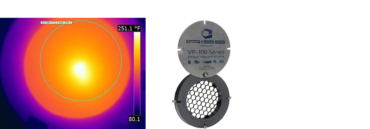

With all the above in mind, we at IRISS have introduced a revolutionary new polymer IR window called the Platinum Series. It allows IR, visual, and ultraviolet transmission while keeping our industrial strength capabilities. We strongly suggest that when purchasing a new style window or a new IR camera, consider measuring the transmission rate with the new setup. You may indeed find that the transmission rate is now different. That is the effect of dealing with a selective radiator.

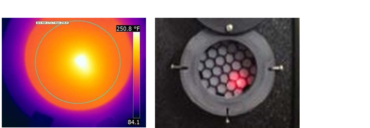

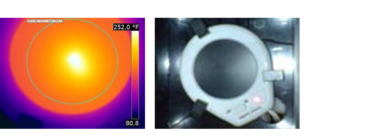

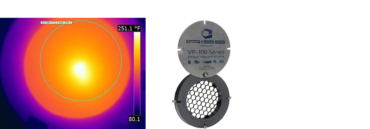

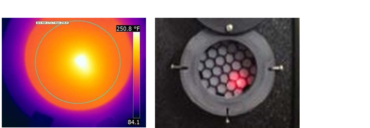

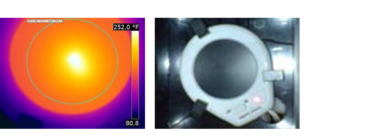

Now to test our IRISS window with the original milky polymer of the VPFR Series with safety grill alongside the new Platinum Series with safety grill. The test will involve a simple transmissivity measurement of both windows using a FLIR P640 IR camera.

IRISS VPFR Series IR window with transmissivity set to .42 (42%) to achieve the original temperature of 256°F

Max temperature of target (no IR window) is 256°F

IRISS Platinum Series IR window with transmissivity set to .44 (44%) to achieve a result of 256°F

Conclusion

Transmissivity values may not be the same from one window to another even when the materials are similar. These values must be measured by each type of camera as well and will depend on the spectral response of the camera detector and the realbody nature of all materials. The good news is that once you find that value, you can apply it to all of your IRISS windows of the same material. And now that you know the value, you can achieve accuracy when optimizing your software or thermal IR camera’s parameters.