The motor and associated cabling have service factors to consider for your process environment as does the equipment you use to monitor your uptime.

Variables to consider when replacing your motor and cabling are operating environment temperatures, conditions of process (wet, dry, dirty, etc.) and the process load. Ambient temperature at the facility may increase during the process phase of the activity. Over time the heat will transfer to other parts of the motor. Motor insulation classifications help determine the requirements for the optimal motor insulation to operate at a temperature rating for a specific operating lifecycle. This is the rise in temperature above the ambient temperature of the process environment to a maximum.

A given rating does not determine that an electric motor will run forever rather, it means that the insulation used on the motor winding should not fail at specific temperatures and then age and degrade as normal over the life of the motor. At some point the insulation reaches a point where the applied voltage is no longer able to be con- tained and a short or open winding may occur. NEMA (National Electric Manufactures Association) develop tech- nical standards for electrical equipment and rates motors as Class A through H. An A rated electrical motor being lower temperature (105 degrees Centigrade) and H (180 degrees C) being the highest temperature with specific temperature rises and hot spots (center point of the motor’s winding where the temperature is higher). Having the correct motor insulation for your environment is critical for uptime. Arrhenius equation states that chemical reaction rates double for every 10° C temperature increase. Operating motors above the maximum temperature rating will rapidly degrade the life of the insulation and the motor life.

Environmental conditions have a direct impact on your motors. Starting with the right motor and cabling help ensure uptime. To understand, track or trend the condition of motors and cables, ATP recommends the use of MCA™ technology.

Environmental conditions have a direct impact on your motors. Starting with the right motor and cabling help ensure uptime. To understand, track or trend the condition of motors and cables, ATP recommends the use of MCA™ technology.

Motor Circuit Analysis™ tests all cabling, connections and electrical motor, without advanced electrical knowledge, use of multiple test points, and excessive time (test motor at motor control or at motor in under 3 minutes). MCA™ can determine motor health (rotor& windings), cabling and connection issues, VFD issues, and other troublesome issues that cause motors to fail, stop, run intermittently, and cause process problems. MCA™ is the only field proven, patented electrical technology in the world that can find early winding faults in motors, generators, transformers, or any coil in their earliest stages before they begin to cause problems.

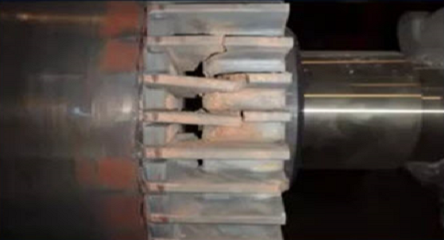

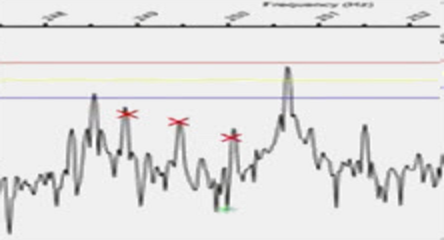

MCA™ fully exercises the winding insulation system to identify the slight changes in the winding insulation system occur over time. To determine winding health, MCA™ measures multiple standard electrical measurements of resistance, inductance, impedance, currency frequency response, phase angle, dissipation factor, resistance, and capacitance to ground to evaluate both the winding and the groundwall insulation systems. MCA™ uses a proprietary algorithm to create a single value,TVS, that defines the condition of the winding and rotor system. Changes in the TVS indicate changes in the motor and the motor’s health. The patented MCA™ dynamic test can be performed by simply manually rotating the motors rotor while the motor is deenergized to create the (dynamic rotor signature) & the stator (dynamic stator signature). This test can be performed on the plant floor to determine the status of the rotor & winding in 3 conditions, OK, Warn, or Bad. MCA™ automatically evaluates the condition of the motor using easy to follow on screen instructions. Testing the motors remotely from the MCC locates developing faults in the cabling, motor or even faults in the controller.

MCA™ fully exercises the winding insulation system to identify the slight changes in the winding insulation system occur over time. To determine winding health, MCA™ measures multiple standard electrical measurements of resistance, inductance, impedance, currency frequency response, phase angle, dissipation factor, resistance, and capacitance to ground to evaluate both the winding and the groundwall insulation systems. MCA™ uses a proprietary algorithm to create a single value,TVS, that defines the condition of the winding and rotor system. Changes in the TVS indicate changes in the motor and the motor’s health. The patented MCA™ dynamic test can be performed by simply manually rotating the motors rotor while the motor is deenergized to create the (dynamic rotor signature) & the stator (dynamic stator signature). This test can be performed on the plant floor to determine the status of the rotor & winding in 3 conditions, OK, Warn, or Bad. MCA™ automatically evaluates the condition of the motor using easy to follow on screen instructions. Testing the motors remotely from the MCC locates developing faults in the cabling, motor or even faults in the controller.

Environmental conditions have a direct impact on your motors. Starting with the right motor and cabling help ensure uptime. To understand, track or trend the condition of motors and cables, ATP recommends the use of MCA™ technology.

Environmental conditions have a direct impact on your motors. Starting with the right motor and cabling help ensure uptime. To understand, track or trend the condition of motors and cables, ATP recommends the use of MCA™ technology. MCA™ fully exercises the winding insulation system to identify the slight changes in the winding insulation system occur over time. To determine winding health, MCA™ measures multiple standard electrical measurements of resistance, inductance, impedance, currency frequency response, phase angle, dissipation factor, resistance, and capacitance to ground to evaluate both the winding and the groundwall insulation systems. MCA™ uses a proprietary algorithm to create a single value,TVS, that defines the condition of the winding and rotor system. Changes in the TVS indicate changes in the motor and the motor’s health. The patented MCA™ dynamic test can be performed by simply manually rotating the motors rotor while the motor is deenergized to create the (dynamic rotor signature) & the stator (dynamic stator signature). This test can be performed on the plant floor to determine the status of the rotor & winding in 3 conditions, OK, Warn, or Bad. MCA™ automatically evaluates the condition of the motor using easy to follow on screen instructions. Testing the motors remotely from the MCC locates developing faults in the cabling, motor or even faults in the controller.

MCA™ fully exercises the winding insulation system to identify the slight changes in the winding insulation system occur over time. To determine winding health, MCA™ measures multiple standard electrical measurements of resistance, inductance, impedance, currency frequency response, phase angle, dissipation factor, resistance, and capacitance to ground to evaluate both the winding and the groundwall insulation systems. MCA™ uses a proprietary algorithm to create a single value,TVS, that defines the condition of the winding and rotor system. Changes in the TVS indicate changes in the motor and the motor’s health. The patented MCA™ dynamic test can be performed by simply manually rotating the motors rotor while the motor is deenergized to create the (dynamic rotor signature) & the stator (dynamic stator signature). This test can be performed on the plant floor to determine the status of the rotor & winding in 3 conditions, OK, Warn, or Bad. MCA™ automatically evaluates the condition of the motor using easy to follow on screen instructions. Testing the motors remotely from the MCC locates developing faults in the cabling, motor or even faults in the controller.