In this one, we are going to discuss rotor casting voids—whether they are fact or myth.

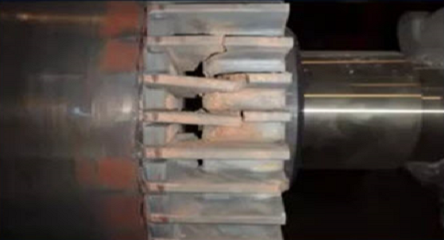

They are definitely fact. Casting voids do exist, as you can see here. This is a rotor that’s been segmented while doing an investigation. You can see a casting void on the upper left, and you can see little voids here and there throughout this particular cast aluminum rotor.

They do exist; however, it wasn’t until the late 1980s that we started really noticing these with new technology. So it became more and more prevalent that we were seeing casting voids. Casting voids have always existed in cast rotors, regardless of the casting material.

So what is the impact of a casting void? Well, we can have some that are large enough to impact the flow of current in the rotor. Or, in the worst case, we can have casting voids that will cause rotors to come apart during operation.

How do we detect them? There are several ways of detecting them, and one way, which we will discuss in this presentation, is with electrical or motor current signature analysis.

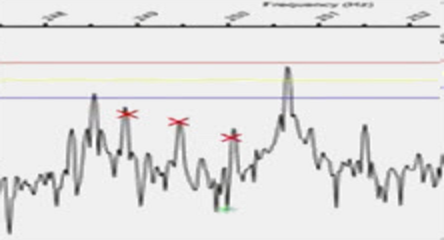

Usually, if I have a casting void, I’ll see a fair amount of balancing weight on the rotor. Casting voids in machines will show up as pole pass frequency sidebands. In this case, you can see two blue arrows (on either side of a sharp peak, on a spectrum shown in the video). Those are pointing to casting voids. On the upper right, you can see the air gap torque inside a machine. Just because I have a casting void—in this case, this is about 58 dB down—do I consider these serious or not? Let’s discuss that.

Really, what I’m more concerned about with casting voids is that they will interrupt the motor’s ability to produce torque, such as with a broken rotor bar in a copper bar application. We’ll talk about that at the end. But in the meantime, just because I have casting voids, it doesn’t necessarily mean that the motor will not produce torque.

In this case, let’s look at one that I tested this week. This is a 400 hp, 1700 rpm motor tested with a dynamometer. We do have pole pass frequency sidebands right around the two blue arrows (on the spectrum), and you can see that the blue arrow on the very bottom (on the demod spectrum) points to the pole pass frequency. These other frequencies beside it to the right (on the demod spectrum) are actually from the dynamometer itself—those peaks are related to some conditions that exist within this particular dynamometer, so we only have two peaks there. Now you’ll notice up on the top, my RMS current is fairly flat; there is some ripple in it, and some of that relates to the gear issue, and some of that relates to the pole pass frequency. These pole pass frequencies are 50 dB down, or minus 50 dB—that’s the dB from the top of the line frequency current.

Taking a look at this table (PPF Levels and Corresponding Rotor Condition) —this table was developed by Oak Ridge National Laboratory in the early 1980s—I can see at 50 dB down, I have a condition that I’ll want to trend. In this case, with casting voids, you just notice that they’re there and you’ll trend them, so long as it’s not affecting the motor’s ability to produce torque or its efficiency.

In the case of the 400 hp motor, you can see (on the machine torque graph) there’s a small ripple here. Some of that relates to the gear. This middle piece here shows what’s going on in relation to the casting void, and you can see it’s not very significant. There is some small variation in torque—this is actually normal. So I would say that I’m not seeing an impact in relation to the torque in the motor. It did run up to proper speed; we did bring it up to around 300 hp when testing it, and we didn’t see any significant change. It produced what it was supposed to produce, and it ran at the speed it was supposed to run.

This is what a broken rotor bar looks like. I have pole pass frequency variations with my current. I have pole pass frequency sidebands, and as a matter of fact I have two sidebands. This usually indicates that I have at least one good rotor bar in between a series of bad rotor bars. In this case, this is a copper bar machine. It did have significant casting voids. It had to be serviced and corrected.

In conclusion, casting voids do exist in machines. The only time I seriously worry about them is if they’re serious enough to impact the motor’s ability to produce torque. Other than that, they’re balanced out, they cause very low variation in the air gap torque, and for the most part, they are normal in the machines. It’s just that we can see them now and we couldn’t before.