CASE STUDY: Predictive Maintenance Team Saves Steel Mill Time and Money with Thorough Motor Testing

The Company

Gerdau is one of the largest producers of steel and steel recycling in North America, with an annual manufacturing capacity of approximately 10 million metric tons of steel products. Their operation in Midlothian, Texas, maintains an inventory of about 70 cranes which range in size and use throughout the steel mill and materials recycling facility. The steel mill’s in-house predictive maintenance team inspects the overhead cranes on a quarterly basis. When the predictive maintenance team was alerted by the ALL-TEST PRO 5™ de-energized motor testing instrument to a potential problem, the technicians took steps to get to the root cause of the issue.

What is Motor Circuit Analysis™?

A low-voltage, non-destructive AC signal is sent through the motor windings to measure the response to these signals. The phase angle (Fi), the current/frequency response (I/F), the impedance (Z), the resistance (R) and the inductance (L) of each winding is measured and the unbalances of these measurements are compared. Winding faults are indicated by variances in the response to the applied signal through the windings. These variances cause unbalances in the measured response to the applied signal. Therefore, when testing 3-phase equipment such as motors, generators, or transformers, the response of each phase is compared to the other two. Phase resistance is evaluated to determine connection issues; Inductance is evaluated for possible rotor problems; Impedance and inductance matching are used to detect contamination or over-heating of the windings; Insulation-to-ground tests detect conductor-to-ground issues.

Quarterly Testing Suggests Motor Degradation (but thorough testing finds otherwise!)

The Materials Recycling #4 Scrap Crane Trolley Motor was scheduled to be inspected the first week of March 2017. An AT5™ de-energized motor testing instrument would be used to perform a Motor Circuit Analysis (MCA™), which enables a reliability/maintenance technician to determine the condition of the electric motor’s windings. The AT5™ had been purchased in 2016 because it is a hand-held instrument that was more portable than the steel mill’s 60-pound testing instrument that had required a dedicated 110-volt power source.

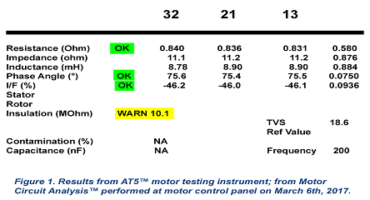

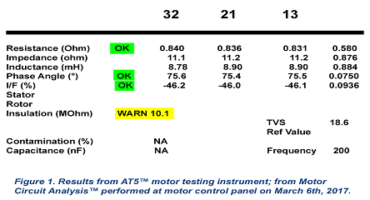

The AT5™ was connected to the motor control panel and a Motor Circuit Analysis™ was performed on the 20-horsepower trolley motor. Within only a few minutes’ time, the test results showed a disconcerting insulation-to-ground readout of 10.1 Meg-ohms (see Figure 1).

“This difference in test results raised some red flags for the predictive maintenance team.”

This ‘practically new’ motor, which had been installed onto the crane in October of 2016, was tested at the time of its initial installation. That very first test had shown a reading of greater than >999 Meg-ohms. This difference in test results raised some red flags for the predictive maintenance team. Seeing as how the motor had only been in operation for six months, it was clear that the motor should not have deteriorated that quickly.

Finding the Real Problem

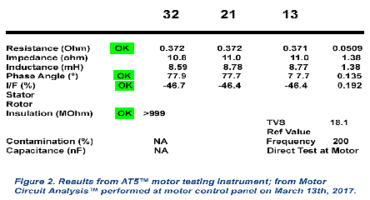

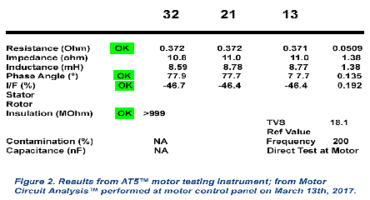

The predictive maintenance team scheduled a retest of that same motor the following week; however, this time, the AT5™ would be connected directly to the motor.

Within minutes of performing the second test, the AT5™ reported an insulation readout of greater than >999 Meg-ohms (See Figure 2). At this point, the predictive maintenance team realized the issue was not with the motor, but lay within the festoon cabling from the motor control cabinet up to the trolley motor. The cables from the drive to the festoon trolley junction box were checked for damage and then promptly replaced.

Learn from this Predictive Maintenance Team!

They test their new motors at installation.

It is important to test new motors at the point of installation. If a ‘new’ motor is being installed after having been stored for a significant period of time, testing it will confirm that the motor will operate as promised. Testing at the point of installation might help to uncover problems that can be resolved within the warranty period. From a long-term standpoint, motor testing will also establish baseline data that may come in handy for future maintenance review and decision-making.

They continued testing instead of immediately replacing the motor!

This predictive maintenance team didn’t waste any time trying to replace a motor that was in perfectly good condition. They knew how much time and resources would be required to replace the motor – an overhead crane would be needed, multiple technicians, more people and more man-hours. That all adds up! By getting to the root of the problem, they saved time and money.

They used a reliable testing instrument.

The AT5™ motor tester has proven to be an invaluable tool for motor diagnostics. It’s lightweight, portable, and shows results right away. This predictive maintenance team figured out the real problem right away and was able to fix the issue quickly so they could move on to other projects.

About ALL-TEST Pro, LLC.

ALL-TEST Pro delivers on the promise of true motor maintenance and troubleshooting, with innovative diagnostic tools, software, and support that enable you to keep your business running.

About Gerdau

Gerdau is a 110-year-old old steel company, leading producer of long steel in the Americas, and one of the world’s largest suppliers of specialty long steel.