Let’s start by explaining the FTIR index numbers and then we’ll get in to the correlation between tests.

The indexing numbers actually refer to a unit of measure. The unit is absorbance/0.1mm. However, this unit of measure is not one that is intuitive to most people so the results are referenced as Indexing Numbers.

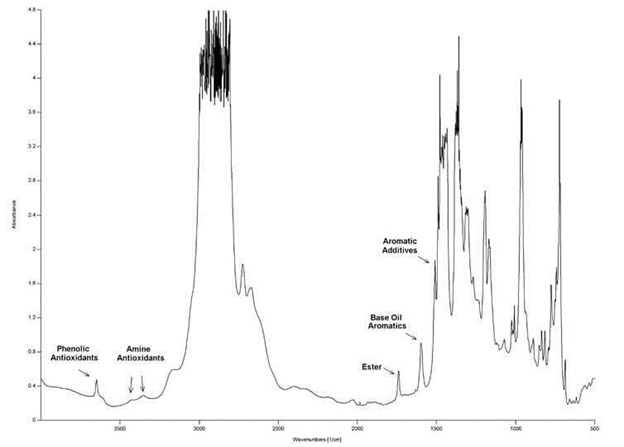

The unit, abs/0.1mm, relates directly to the peak intensities in the FTIR spectrum. The spectrum is a graph of peaks and valleys composed by the FTIR instrument that reports the molecular makeup (how different atoms are bonded to one another) of the lubricant sample. The FTIR instrument is actually determining the area of specific peaks within the spectrum to give the numbers seen on the reports, so these numbers are related to the area under a curve rather than an actual percentage. Information from the FTIR parameters are best used in trend analysis because most of the results do not directly relate to the concentration of a particular parameter (phenolic, acid oxidation, etc.), unlike ppm or %.

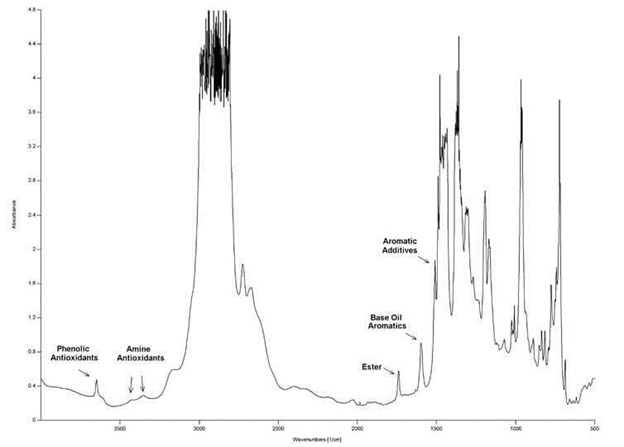

Below is an FTIR spectrum. The various peaks associated with the FTIR Turbine Method are indicated.

Now, the main question received regarding index numbers is, why aren’t the new oil/reference numbers 0 or 100? First off, we now know that the FTIR Turbine Method number is not referring to an exact concentration and is actually referring to the area under the peaks associated with the parameters. On the other hand, many of the new oil index numbers are not 0 to start because many oils contain peaks within the areas the parameters look at. In the spectra above looking at the oxidation number for example, the new oil (orange spectrum) contains chemistry that shows up in the area where the oxidation parameter looks. With the oxidation number we typically expect that starting number to increase as the lube ages/degrades. On the other hand, with additives we expect the index number to decrease as the additives deplete as with the Phenolic parameter in the FTIR Turbine Method.

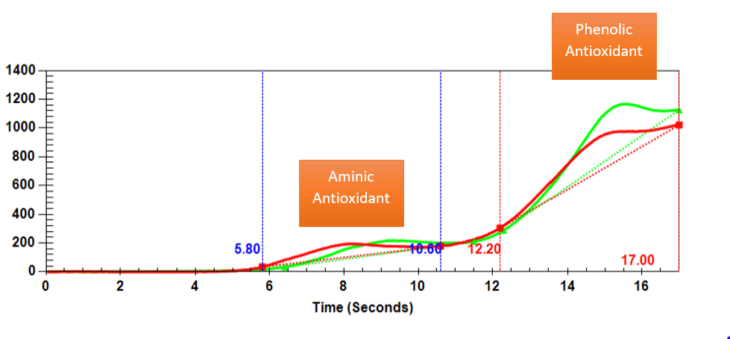

On to the correlation of the RULER and FTIR Phenolic parameter:

The RULER was developed to specifically look at the phenolic and amine antioxidants found in R&O lubricants. The nature of the RULER allows it to better detect amines and phenols in the lube. FTIR is very good at giving us an overall look (fingerprint) of the oil, but it is not as good at specifically detecting amines and phenols. In part because many chemistries such as water, varnish, other contaminants can actually interfere with the FTIR’s ability to detect the phenols in the oil so it is wonderful that we have another tool, the RULER, to help specifically look at those additives of interest.

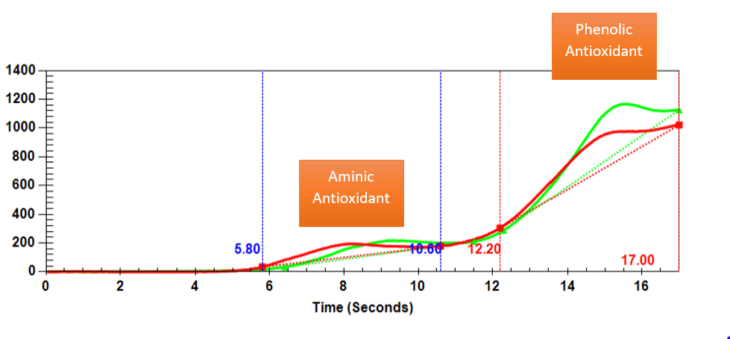

Below is RULER data with the Phenolic Antioxidant parameters indicated.

So, based on the fact that the RULER is more sensitive to the presence of phenols than the FTIR we expect that the RULER will detect a decrease in the additive before the FTIR will. Then, eventually the FTIR Phenolic index number will start to decrease. This is why we use RULER as the primary test for detecting phenols and FTIR is the secondary test. On the flip side, if makeup oil is added I expect to see a more significant increase in the RULER data than I do the FTIR data.